|

CHAPTER TWO |

Prior to the establishment of this research program, foundation engineering

guidelines were mostly empirical and barely sufficient for most highway

applications. The result was an inability to accurately predict the performance

of foundation systems, which, in turn, led to very conservative design

procedures as well as an occasional foundation failure. A comprehensive research

plan was initiated in the late 1970's to develop improved design and

construction guidelines for building safer and more cost-effective bridge

foundations. Engineering improvements were expected to reduce the cost of these

foundations and stretch the highway dollar to buy more bridges that will last

longer.

An analysis of future needs for highway bridge foundations was

completed under this project to provide essential planning information for

conducting effective research on bridge foundations. Estimates of the number of

new bridges to be constructed and those that would need to be replaced or

rehabilitated during the remainder of this century were made in 5-year

increments using data from FHWA bridge inventory and inspection reports. An

analysis of FHWA foundation management review reports was also made to determine

typical foundation types used in each State and likely to be used on future

construction. The analysis was also supplemented with personal interviews with

selected State and FHWA bridge engineers from various regions of the country

(1).

Results of these analyses indicated that more than 100,000 bridges

would be constructed, replaced, or rehabilitated in the United States during the

last 20 years of this century. Approximately 20,000 new bridges would be built

and more than 15,000 existing bridges had deficient foundations. Many of the

satisfactory foundations would also have to be replaced because of retrofit

problems caused by replacing the superstructure. A large number of reusable

foundations required special design and construction procedures that needed to

be developed. It was also noted that more than two-thirds of these bridges were

likely to be supported on piles, one-fourth of them on spread footings, and the

rest of them on drilled shafts or other types of foundations (1).

![]()

2.1 Background

Because the safety and cost-effectiveness of bridge foundation systems is of

major importance, an appropriate research program to develop better design tools

has long been advocated by both structural and geotechnical engineers.

Foundations represent about 30 percent of the cost of highway bridges in typical

applications; however, this cost can be even higher where bridges are built near

or on difficult soil conditions. The total annual expenditure of public funds

for bridge construction is conservatively estimated to be more than $2 billion,

which means that foundations are costing more than half a billion dollars per

year.

Because the predominant type of foundation system used in the

highway industry is piles, the first priority for this project was the efficient

design of piles. Research was also needed to develop new concepts for reducing

our excessive reliance on pile foundations. In situations where deep foundations

are required, the overall cost can be significantly reduced by using smaller

piles and fewer of them as a result of design economies developed under this

research project.

The indiscriminate use of pile foundations was partly

due to a lack of confidence in the safety and dependability of drilled shafts

and shallow foundations, but mainly due to unreasonably restrictive deformation

and movement constraints. Therefore, the establishment of rational criteria for

tolerable movements was a necessary first step toward improving foundation

design (see section 2.5).

Assuming a 25 percent reduction in the use of

piles can be accomplished by substituting cheaper drilled shaft or shallow

foundation units, the use of piles will still account for much more than half

the foundation systems used for highway structures. Therefore, the continued

investigation of pile-soil behavior will provide cost-effective improvements.

One of the most incongruous aspects of foundation design is the overwhelming use

of a system (friction piles) that is the least understood.

2.2 Objectives

The overall project objective was to develop improved foundation design and

construction methods for highway bridges. This objective was approached through

efforts directed toward accomplishment of the following four separate, but

related goals:

2.3 Scope

Research efforts in this project were directed toward developing new predictive techniques for foundation design, better criteria for tolerable movements, and permissible stress levels in piles and drilled shafts, as well as improved construction control techniques. Each component of the total foundation system was studied individually and each total system was evaluated as a whole. The behavior of the foundation systems was also examined under both working and ultimate stresses.

2.4 Project Description

The major research efforts were organized into five tasks:

The Foundations Project was the "flagship" project of the FHWA Geotechnology Research Program. It could and probably will be a separate report by itself; in fact, each of the five main tasks could also be a separate report. The following six sections of this chapter provide a summary of the major highlights of this project.

2.5 Structural Consequences of Foundation Movements

During the development of the FHWA research project on foundations, it was

determined that one of the major reasons that bridge foundations were

over-designed had its roots in the lack of rational criteria for tolerable

movements of the superstructure. The American Association of State Highway and

Transportation Officials (AASHTO) design code at that time was relatively silent

in this area, and basically promoted a "zero" settlement design procedure. This

resulted in a very high cost of obtaining little or no settlement in terms of

utilizing the soil load-carrying capacity because it is almost impossible to

achieve this objective. The cost was often extremely high and very

wasteful.

Foundation movements under highway bridges (figures 1 and 2)

had occasionally been predicted and measured; however, there had been very few

investigations of the effect these movements would have on the safety and

serviceability of the bridge structure. As a result, tolerable foundation

movement had not been established beyond the conceptual stage, and much

controversy among engineers was prevalent.

In addition to the

disagreement on the definition of tolerable settlement, there was also

disagreement on the accuracy of settlement predictions. As a result, many

engineers still prescribed strict settlement constraints to guard against

erroneous predictions. In many cases, the precautions were unrealistic and

underestimated the accuracy of the prediction techniques, which are normally

accurate within 10 to 20 percent on average and are rarely more than 50 percent

off the measured value.

It was noted in earlier studies that using piles

did not guarantee that there would be little or no settlement, unless the piles

were founded on hard rock. The nature of load transfer from the pile to the soil

surrounding (side friction) and beneath the pile (tip bearing) requires some

movement of the pile to mobilize the load-bearing capacity of the soil material.

The relative movement required to mobilize maximum frictional strength is

approximately 6.35 mm (0.25 in), while the displacement required to mobilize the

soil's shear strength under the pile tip is usually much larger than that value.

If the allowable settlement is restricted to a smaller value than what is

required to mobilize tip resistance, the load-carrying capacity of the pile is

artificially reduced to the level of side friction support. The support capacity

available at the pile tip then becomes an additional safety factor.

FIGURE 2. Bridge girder jammed against abutment and excessive rocker tilt.

Overly restrictive settlement constraints can reduce significantly the

supporting capacity of friction piles. To comply with the prevalent requirements

of zero or near zero settlement, the foundation engineer must reinforce his or

her design by adding more piles, using longer piles, or increasing the diameter

of the piles. The conservative effect of this design philosophy is evident by

examining any load-settlement curve from a pile load test. A slight increase in

the allowable settlement value can impact significantly the allowable design

load for a pile foundation, especially within the straight line portion of the

curve.

A relaxation of the stringent movement criteria was also expected

to impact significantly the use of spread footings, whose major drawback is the

risk of some settlement. Because the economic breakpoint in the normal design

procedure for spread footings centers around 25 mm (1 in) of settlement,

the majority of bridge engineers were reluctant to use this less expensive

method of foundation support. As a result, the highway industry has been accused

of having numerous "buried treasures" beneath bridge abutments and piers,

because piles were used instead of spread footings or because more and/or larger

piles were used than necessary.

Research performed under this project

indicated that bridge structures can withstand a reasonable amount of

settlement, and the amount varies according to the span arrangement (simple

versus continuous) and length of span as well as other design variables. This

indicates that the AASHTO blanket criterion approach was inappropriate and the

zero settlement design approach was too conservative.

2.5.1 Preliminary Studies – Prior to the initiation of a

comprehensive research study by FHWA, a series of smaller studies that were

conducted in Ohio, Washington, Connecticut, Canada, and by FHWA staff were

evaluated to help develop a detailed research plan. Studies done for the

building industry were also included in the evaluation. A study of the measured

movement data and corresponding damage assessments were very enlightening, but

insufficient to establish rational tolerable movement guidelines. It was also

noted that the building codes in many major U.S. cities actually permitted

larger settlements than AASHTO bridge specifications, even though building

elements, such as glass doors and windows, elevator shafts, utility lines, and

brittle wall panels, are more sensitive to foundation settlement than bridge

elements.

Although no well defined set of criteria was generally agreed

upon, all of the researchers agreed that the development of a rational set of

tolerable movement criteria for bridges was a high priority research need.

Everyone then turned to FHWA's Office of Research to conduct a major effort to

solve this problem.

2.5.2 FHWA Tolerable Movement Study – A comprehensive

analysis of the data from the earlier studies that evaluated field measurement

surveys was conducted as part of an overall analytical investigation of the

effect of different magnitudes of settlement on the potential level of distress

produced in a wide variety of steel and concrete bridge structures of different

span lengths and stiffnesses. A total of 314 bridges in the United States and

Canada was analyzed to determine if the measured foundation movements and

corresponding damage assessments could yield sufficient insight toward the

development of rational criteria for tolerance to movement. The data by

themselves proved to be insufficient, but when combined with the structural

analysis studies, and an appraisal of existing design specifications and

practice, a rational set of criteria was developed.

The researchers

determined that functional distress is more difficult to assess than structural

distress because of its subjectivity. Functional distress is defined under this

study as damage to the architectural elements or a reduction in ride quality.

Architectural damage is less severe than structural damage that affects the

integrity of a main supporting element of the bridge; however, architectural

damage is usually more visible and causes an annoying or insecure feeling on the

part of the motorist. It is also referred to as "cosmetic damage" and includes

cracking or misalignment of bridge railings, curbs, decks, abutment wing walls,

and damage to light poles and utility lines. The deterioration of ride quality

involves the "bump" at the end of the bridge and other roadway unevenness

associated with bridge foundation settlement.

The specific results of

this study have shown that, depending on type of spans, length and stiffness of

spans, and the type of construction material, many highway bridges can tolerate

significant magnitudes of total and differential vertical settlement without

becoming seriously over-stressed, sustaining serious structural damage, or

suffering impaired riding quality. In particular, it was found that a

longitudinal angular distortion (differential settlement/span length) of 0.004

would most likely be tolerable for continuous bridges of both steel and

concrete, while a value of angular distortion of 0.005 would be a more suitable

limit for simply supported bridges.

For continuous steel bridges,

differential settlements of 25 mm (1 in) or more would be intolerable for span

lengths up to 15.2 m (50 ft) because of the significant increase in stresses

caused by these settlements. However, for span lengths between 30.5 and

61.0 m (100 and 200 ft), the stress increases caused by differential

settlements up to 76 mm (3 in) were quite modest, and for spans longer than

61.0 m (200 ft), the stress increases caused by 76 mm (3 in) differential

settlements were negligible.

A basic design procedure was developed that

permits a systems approach for designing the superstructure and the foundation

system. This design procedure incorporates the tolerable movement guidelines

that are based on strength and serviceability criteria which, in turn, are based

on limiting longitudinal angular distortion, horizontal movements of abutments,

and deck cracking (2,3).

2.5.3 Publications and Implementation Items – Research and development activities for the establishment of tolerable movement criteria were very successful. The FHWA R& D reports documented the efforts that were made to develop the rational criteria and presented detailed recommendations on how the new criteria should be used in typical bridge and foundation engineering scenarios. A technology sharing report was developed to help practitioners implement the new criteria in standard design situations (4). Workshops and presentations were also held to aid the implementation process. A new article was developed for the AASHTO Bridge Specifications (see chapter 7).

2.6 Pile Foundations

The first difficult problem confronting the designer of a foundation is to

establish whether or not the site conditions are such that piles should be used.

The most common case is that in which the upper soil strata are too compressible

or generally too weak to support heavy vertical reactions transmitted by the

superstructure. In this instance, piles serve as extensions of columns or piers

to carry the loads to a deeper, more rigid stratum such as rock (point-bearing

piles). If such a rigid stratum does not exist within a reasonable depth, the

loads must be gradually transferred by friction along the pile shaft. Scour and

the relative inability of spread footings to transfer inclined, horizontal, or

uplift forces and overturning moments also require the use of piles in many

instances.

Another problem facing the pile designer is choosing from

among the 100 or more different kinds of piles. There are many variations in

materials, configurations, and installation techniques. Guidelines for selecting

the best pile for various situations can be found in one or more of FHWA's

guidance manuals (5, 6, 7) and the general literature.

After a particular

kind of pile has been selected for use, the designer then must determine the

number, length, and size of the piles required. Simple guidelines were not

available at the start of this research program to design and analyze piles for

the various situations that can occur in bridge foundations; however, improved

pile design guides are now available in various FHWA references listed at the

end of this report. The ultimate load that can be supported by a certain kind of

pile depends on the strength of the soil and/or pile material. Usually the

ultimate load is determined by soil failure; however, the pile itself may fail

if forced to penetrate difficult site conditions such as dense soil or

rock.

Calculating the ultimate load on the basis of soil failure is one

of the most difficult problems confronting the foundation designer. Because

available theories for determining the ultimate load of a pile and a group of

piles were not accurate enough to provide economical foundation designs,

research was conducted to define the complex mechanics of load transfer between

pile and soil and among the various piles within a pile group. Load transfer in

piles and pile groups was measured in the laboratory and field to develop and

refine analytical models of the pile behavior process to provide more economical

design procedures.

Assuming the pile material is not over-stressed, the

ultimate load capacity of a pile is equal to the sum of two major soil

components — point resistance and side friction. The amount of support

contributed by each component varies according to the soil properties and pile

dimensions. These resistances can be calculated through mathematical

relationships; however, the required input data are difficult and expensive to

obtain. As a result, less expensive index testing usually is performed to obtain

approximate values for estimating the resistances.

Pile capacity usually

is predicted using static and dynamic analysis procedures. On large, expensive

structures, pile load tests often are used to verify the design loads. Recently

completed FHWA experimental studies of instrumented piles load tested to failure

have increased our understanding of load-transfer behavior of single piles and

pile groups; however, more tests are needed to confirm the new prediction

methods.

A mathematical model of pile group behavior was deemed to be a

valuable analytical tool that systematically can convey engineering experiences

from one site to another. Several mathematical models had been developed,

including one by FHWA; however, none had been validated adequately because of

the lack of precise field data on pile group behavior. This was especially true

of new foundation design methods based on finite element analysis. To date FHWA

has performed most, if not all, of the pile group load tests to failure. These

results have been used to validate and refine the FHWA pile group design model

called PILGP (8).

2.6.1 Areas of Emphasis – Because of the high reliance on

driven piles, a large portion of FHWA funds for foundation research was directed

at improved design and construction procedures for driven piling. FHWA pile

research was divided into the following three major areas of emphasis:

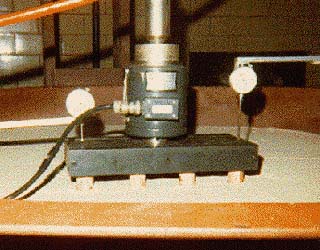

2.6.2 Single Piles in Clay – Field load tests on single

piles in soft clays have provided experimental data to evaluate a promising pile

capacity predictive technique based on the general effective stress method. The

effective stress method for predicting pile capacity was validated and its

accuracy and general applicability were improved. Figure 3 shows a full-scale

pipe pile being instrumented in the laboratory prior to field

installation.

The accuracy of the method was limited by the assumptions

made to describe the changes in effective stress between pile driving and

subsequent loading. Major uncertainties arise in attempted modeling of the

effective stresses after the disturbed soil has reconsolidated. Current analysis

techniques were considered applicable to full displacement piles driven into

normally consolidated clays (9).

|

| |

|

FIGURE 3. Lab instrumentation of a pipe |

FIGURE 4. Field instrumentation of a pipe |

2.6.3 Single Piles in Sand – Previous methods for predicting

the behavior of driven piles in sand gave widely different results because of

several sources of error. Variability of the soil and methods used to obtain the

design parameters also contributed to the different results as did some of the

simplifying assumptions made in developing the theoretical methods.

An

FHWA research study on the behavior of piles in cohensionless soils involved the

analysis of data on instrumented piles (figure 4) tested to failure under

vertical loads. The data, collected through an extensive literature search,

consisted of 35 pile load tests at 10 different sites. The piles were of various

kinds, lengths, and diameters and included steel pipe and H-piles and

prestressed concrete and timber piles. Average pile diameter was 0.4 m (1.27

ft), and average pile length was 15.1 m(49.6 ft ).

Statistical

analyses determined the vertical and horizontal variability of the soil at each

case history site. Load transfer characteristics were analyzed for each pile

without consideration of residual driving stresses. In those few cases where

residual stress data were available, the load transfer characteristics were

reanalyzed to learn the effect of residual driving stresses. It was found that

residual stresses play an important role in pile design and that proper

consideration of residual stresses can result in shorter pile lengths for driven

piles in sand (10).

2.6.4 Allowable Stresses in Piles – In addition to the

ability of soil or rock to carry the load transferred from a pile, the load

capacity of the pile also is important. The load capacity of a pile is governed

by its structural strength and, to a lesser extent, by the surrounding

environmental conditions. The structural strength is a function of the allowable

stress levels that apply to the particular pile material and the cross-sectional

area of the pile.

To provide a factor of safety against failure (figures

5 and 6), allowable stress levels normally are specified as a percentage of the

peak strength value of the pile material (for example, steel, concrete, or

timber). Allowable stress levels for piles vary significantly because of

different building codes in different jurisdictions. Significant controversy had

arisen concerning the allowable stress levels used in the highway industry at

the time of this research project (circa 1980) because the choice of allowable

stress values greatly affects the dimensional analysis and thus the economy of

the foundation system. Another factor to be considered was that competition

between materials producers was keen and significantly affected by changes in

the allowable stress codes.

FIGURE 5. Concrete piles damaged by difficult driving conditions.

FIGURE 6. Steel H-piles badly damaged by hard driving.

A comprehensive investigation of the design of piles as structural members

was performed to define and establish, through structural analysis and

supporting field data, a rational guideline or design methodology for

determining allowable stress levels for pile design codes used in highway bridge

foundations. These methods must take into account not only the material

properties of the pile itself, but also the individual effects of long-term

loads, driving stresses and driveability, imperfections in form or material, and

various environmental conditions that tend to reduce pile capacity.

As

part of the overall review, the investigators studied the codes and

specifications of an array of national and foreign organizations and code

bodies. The basis for each code was reviewed and corroborative data were

assembled to develop improved values of allowable stresses. The claims of

material suppliers for increased allowable stress levels also were evaluated and

documented. Some of the claims were found to be overstated, and all of them

ignored at least one or more of the important factors that govern the structural

strength of a pile.

In general, it was recommended that allowable stress

values in use at that time be decreased for concrete and timber piles and

increased for steel piles. The new procedures for determining appropriate

allowable stress levels on a case-by-case basis according to the major factors

governing structural strength of piles are a significant improvement over the

previously unsubstantiated blanket stress levels. Reasons for each suggested

change to then current methods for determining allowable stress values are

documented in the FHWA report (11).

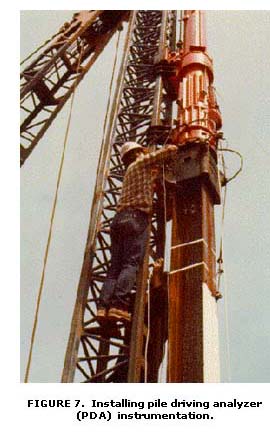

2.6.5 Performance of Pile Driving Systems – Proper construction control of pile driving operations is as essential as good design practices. Construction control is more difficult for piles than for spread footings because the excavation and construction of footings can be observed. The construction control for pile driving involves checking the pile materials and the installation equipment. The pile inspector can visually check many requirements; however, some of the most important checks require instrumentation. The high cost of pile foundations prompted FHWA to seek more efficient pile driving systems as well as more efficient design methods.

Pile driving technology has evolved from an archaic system of pounding a

"stick" in the ground with a heavy mass to a sophisticated system of installing

long, slender structural elements in a well-defined soil mass. In the previous

era it didn't matter how efficient the pile driving system was because the only

objective was to pound the stick into the ground. However, the vertical advance

of a pile under a given hammer blow can be used as a measure of the pile's

bearing capacity. Thus the hammer takes on a second function, and doubles as a

piece of testing equipment. A comprehensive

study of available pile driving systems and corresponding measurement techniques

was completed under this research program. In addition to the direct

measurements of output, researchers investigated the usefulness and practicality

of installing gauges (figure 7) and other instrumentation on the pile driving

system to determine performance rating, spot the cause of erratic or inadequate

operation, and evaluate the significance of erratic behavior in terms of

performance capability.

A comprehensive

study of available pile driving systems and corresponding measurement techniques

was completed under this research program. In addition to the direct

measurements of output, researchers investigated the usefulness and practicality

of installing gauges (figure 7) and other instrumentation on the pile driving

system to determine performance rating, spot the cause of erratic or inadequate

operation, and evaluate the significance of erratic behavior in terms of

performance capability.

The researchers developed three devices to evaluate the field performance of

pile hammers. The ram velocity measurement (RVM) apparatus uses radar to record

ram velocity as a function of time for conversion to kinetic energy for driving.

The study also developed a system that uses piezoelectric accelerometers to

measure pile hammer impact velocity. This system is referred to as AMS (for

Acceleration Monitoring System). Both the RVM and AMS are expensive and

complicated devices for routine use on pile driving projects. A simpler device,

the Saximeter II, was developed for FHWA to aid the pile inspector in log

keeping and monitoring pile driving performance. It electronically measures

blows per minute and converts time duration to the corresponding fall height

(stroke) of the ram, and converts stroke to the potential energy.

An

inspection manual was also developed to aid construction engineers in evaluating

the performance of pile driving systems (12). It can be used to ascertain that

the pile hammer conforms to certain minimum standards, and to record

observations on hammer and driving system behavior. The manual explains the

theory of operation and inspection procedures for various hammer types,

describes all components of the driving systems, includes a glossary of pile

driving construction terms, and provides summary sheets and forms to aid the

inspector in recording the pile installation process. A slide-tape show was also

developed to provide a visual rendering of the inspection manual for

instructional purposes.

2.6.6 Pile Wave Equation Technology – For many years, pile

design used pile driving formulae that were established to relate dynamic

driving forces to available pile bearing capacity. The original dynamic formula

was developed more than a hundred years ago and was based on a simple energy

balance between the kinetic energy of the ram at impact and the resulting work

done on the soil. The concept assumed a pure Newtonian impact with no energy

loss.

A close examination of the pile driving process recently disclosed

that the concept of a Newtonian impact does not apply. It was also noted that

when the hammer strikes the pile, a force pulse is created that travels down the

pile in a wave shape. The amplitude of the pile wave decays before reaching the

pile tip because of system damping properties; however, a portion of the force

in the wave reaches the tip and forces the pile to penetrate the

soil.

Before the demise of the dynamic driving formulae and before the

wave equation analysis was fully developed, pile designers relied on static pile

analyses to predict pile capacity and determine pile sizes and lengths. The

success of this method depended greatly on the accuracy of boring data and the

engineer's ability to properly classify zones in the subsoil with regard to

relative pile support capability. Static analysis methods will always be very

useful because they are much more accurate than the old driving formulae;

however, the value of wave equation type methods has been steadily

increasing.

The wave equation method is a computer based analysis that

was developed from the classical wave theory, which models wave propagation in a

slender rod subjected to an applied force at one end. Modifications to the

classical theory are necessary to account for changes in the traveling wave form

due to pile and soil properties. If the wave is completely dissipated by the

pile material and soil properties before reaching the pile tip, no penetration

will occur. This can be due to either too small a hammer for the pile, or too

small a pile cross-sectional area specified for the length being driven. Wave

equation analysis can detect both of these scenarios before they happen in the

field, plus it can also predict pile damage if too large a hammer is

selected.

Soil data input requires both an understanding of site-specific

soil properties and the effects of pile driving on those properties. These

dynamic properties are known as damping and quake and are roughly correlatable

with soil type. These properties are best determined by experienced geotechnical

engineers. Research was needed to provide better methods to determine soil

damping and quake values from laboratory and/or in situ soil testing equipment

to better predict pile capacity.

2.6.6.1 Pile Capacity Prediction – In response to

this need, FHWA initiated a contract research study to perform an in-depth

assessment of current techniques and potential methods for determining soil

quake and damping input parameters to the wave equation computer analysis

program. The contractor was required to develop a data base of pile foundation

sites containing research-quality soils data, pile driving records, load test

information, and Pile Driving Analyzer (PDA) data. These data were to be used to

make correlations among quake and damping factors, Wave Equation Analysis

Program (WEAP) capacity predictions, and soil test data. It was also a

requirement to locate 6 to 10 actual projects where load testing and dynamic

measurements were made, plus good soil data had to be available to perform the

required correlations to evaluate the newly developed procedures and propose

additional modifications, if necessary.

The following is a reprinting of

the report's abstract:

"Research has been conducted on the potential

improvement of dynamic wave equation analysis methodology using in-situ soil

testing techniques. As a basis for this investigation, the literature was

reviewed and a summary was compiled of efforts made to date on the development

of models and associated parameters for pile driving analysis. Furthermore a

data base was developed containing more than 150 cases of test piles with

research quality data on static load tests, dynamic restrike tests, soil

information, driving system data and installation records. One hundred data base

cases were subjected to correlation studies using the CAse Pile Wave Analysis

Program (CAPWAP) and various static analysis methods. This work yielded dynamic

soil model parameters which did not indicate a specific relationship with soil

grain size" (13).

2.6.6.2

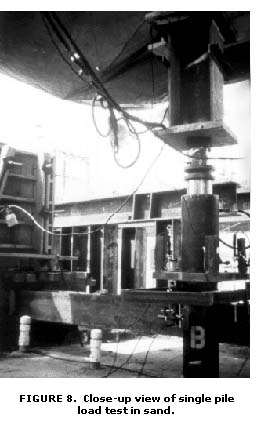

Simplified Capacity Predictions – Static load testing (figure

8) to failure is probably the best method available to determine the actual

static capacity of a pile; however, these tests are expensive and time

consuming. As a result, they are not routinely conducted. In many cases a load

test to twice the design load is conducted to verify safety factors and save

money on the cost to extend the loads to the failure range. These tests give

some measure of assurance to the project design team, but do little to advance

the knowledge of how to design a particular pile in a particular soil. The

simple act of striking a pile with a heavy hammer can also be thought of as an

instantaneous load test to failure; because in order for the pile to penetrate

further into the soil, the soil must fail under the driving forces. In other

words, pile driving is actually a very fast load test under each hammer blow.

With the right type of instrumentation, the engineer can take advantage of these

failure measurements and use the information to make a prediction of potential

static capacity in the field during pile driving operations.

2.6.6.2

Simplified Capacity Predictions – Static load testing (figure

8) to failure is probably the best method available to determine the actual

static capacity of a pile; however, these tests are expensive and time

consuming. As a result, they are not routinely conducted. In many cases a load

test to twice the design load is conducted to verify safety factors and save

money on the cost to extend the loads to the failure range. These tests give

some measure of assurance to the project design team, but do little to advance

the knowledge of how to design a particular pile in a particular soil. The

simple act of striking a pile with a heavy hammer can also be thought of as an

instantaneous load test to failure; because in order for the pile to penetrate

further into the soil, the soil must fail under the driving forces. In other

words, pile driving is actually a very fast load test under each hammer blow.

With the right type of instrumentation, the engineer can take advantage of these

failure measurements and use the information to make a prediction of potential

static capacity in the field during pile driving operations.

This concept

was proposed to FHWA by the developer for further study. The idea to develop a

simplified method based on energy balance between the total energy delivered to

the pile and the work done by the pile/soil system was examined under a research

contract study in the early 1990's. This method, called the "Energy Approach",

uses the calculated transferred energy and maximum pile displacement values from

the measured data, together with the field blow counts as input parameters to

calculate the pile capacity.

To verify and refine the new method, two large data sets were retrieved from

the FHWA Deep Foundations Load Test Data Base (see section 5.2). One set

contains 208 dynamic measurement cases on 120 piles monitored during driving and

followed by a static load test to failure. These cases reflect various

combinations of soil-pile driving scenarios. The other set contains data on 403

piles monitored during driving, but without static load test data.

The

Energy Approach method was found to be very accurate in predicting the pile

capacities that were measured in the static load tests. These estimates were

also found to be more accurate than the sophisticated office methods commonly

used in engineering practice. This comparison was especially true for records

obtained at the end of initial driving. This approach can be used in place of or

as an independent check of the office methods (14).

2.6.7 Micropiles – Micropile technology was conceived in

Italy in the early 1950's to fill the need for an economical and versatile

foundation system that could be used to underpin, repair or retrofit badly

damaged infrastructure elements in war-torn Italian cities. It was introduced in

the United States about 20 years later; however, it did not catch on near as

much as it did in Europe, especially, in the late 1980's and early 1990's. In

addition to static applications, significant growth in the use of this

technology has occurred in seismic and slope stabilization

applications.

All of these uses are directly applicable to highway

projects, which caught the eye and interest of FHWA geotechnical engineers. Two

major earthquakes in California and one in Japan also stirred interest in the

use of micropiles for seismic retrofit of highway bridge foundations. At the

same time, the French Highway Administration began a major research project to

investigate the basic mechanisms and engineering characteristics of micropile

systems.

Micropiles are defined as small-diameter, drilled

piles composed of placed or injected grout with some form of steel reinforcement

in the center of the grout to resist the bulk of the design load. The central

reinforcing element is either a high-strength steel bar or tube that is secured

in the grout that is injected under high pressure to improve bonding with the

surrounding soil. Micropiles can be installed through virtually any ground

condition and at any inclination. Modern construction techniques keep noise and

vibration to a minimum, and they can be constructed under limited headroom

conditions to within a few millimeters of adjacent properties. Figure 9 shows an

early model micropile that was exhumed for inspection purposes.

Micropiles are defined as small-diameter, drilled

piles composed of placed or injected grout with some form of steel reinforcement

in the center of the grout to resist the bulk of the design load. The central

reinforcing element is either a high-strength steel bar or tube that is secured

in the grout that is injected under high pressure to improve bonding with the

surrounding soil. Micropiles can be installed through virtually any ground

condition and at any inclination. Modern construction techniques keep noise and

vibration to a minimum, and they can be constructed under limited headroom

conditions to within a few millimeters of adjacent properties. Figure 9 shows an

early model micropile that was exhumed for inspection purposes.

In 1992

FHWA was invited to become a cooperative research partner in the French

micropile project.

The major objective of this cooperative research

project was to establish reliable engineering guidelines and safe design methods

for the use of micropiles in the reinforcement and stabilization of foundations

and slopes.

It was anticipated that the development of reliable engineering guidelines,

combined with site monitoring for field performance assessment of micropile

systems, would significantly increase the engineer's confidence in the technique

and, thereby, greatly enhance its expansion to new fields of

application.

The initial investigations included a comprehensive review

and critical assessment of available information on current state of the

practice, research case studies, site performance monitoring, quality control

issues, and any comparisons or analyses of current codes of practice. Several

ongoing micropile construction projects were also instrumented and monitored to

provide researchers with additional case histories to study and evaluate. The

major physical experimental tasks involved centrifuge modeling and related

analytical/numerical simulations, full-scale testing, and field monitoring,

which were designed to study the engineering behavior of individual micropiles

and micropile groups and/or systems under axial and transverse load response

modes (figure 10). Buckling, corrosion, and seismic aspects were also

investigated under actual working conditions as well as at failure under

ultimate loading.

FIGURE 10. Load testing of micropiles in California.

2.6.7.1 State-of-the-Practice Review – In 1993 FHWA initiated a contract to produce a comprehensive review document that would delineate all of the known information about micropile technology that could be gathered from various organizations around the world. The contractor put together an international group of experts to evaluate the information obtained in the surveys. The review report (15) provides a comprehensive introduction to micropile technology, and assisted FHWA in developing an engineering guidelines manual (7) containing reliable design guides, construction specifications, and quality-control procedures for the wide spectrum of micropile applications.

2.6.7.2 Seismic Behavior of Micropiles – In 1995, FHWA initiated a contract research study to develop improved seismic design methods for micropile systems used in new construction in earthquake zones, seismic retrofitting of bridge foundations, vertical excavation retainment systems, and slope stabilization. Laboratory centrifugal model tests were conducted to correlate with numerical model studies on various micropile systems (isolated piles, groups, and networks of piles) to evaluate their behavior under axial, lateral, and combined loadings in selected engineering applications. Shaking table tests were also conducted at Christchurch University in New Zealand as part of the overall study to improve seismic design methods. This study is scheduled to be completed after this report is printed.

2.6.8 Publications and Implementation Items – Research and development activities for pile foundations were very successful. Results were documented in numerous reports, and several technology sharing reports were issued to help implement the findings. Several workshops and symposia were held to promote the new guidelines and prediction methodologies that were developed under the research program. Several new articles were added to the AASHTO Bridge Specifications and many others were updated based on the FHWA pile foundation research results (see chapter 7).

2.7 Pile Groups

The state of the art for pile foundation design at the beginning of this

project did not include an accurate method for relating the ultimate bearing

capacity and settlement behavior of a single pile to the behavior of a group of

closely spaced piles. To develop such a method, it was necessary to conduct

field load tests to failure of full-scale pile groups to obtain field data that

were useful in interpreting fundamental phenomena that control the behavior of

groups of driven piles.

Older methods of pile group design treated the

group as a collection of individual piles requiring an adjustment factor.

Predicting the behavior of pile groups required correction of the load capacity

of the individual piles in the group for the interaction effects transmitted

through the soil mass. How this should be done was never certain, and it was

recognized that it would probably be different in cohesive as contrasted to

granular soils.

In 1980, FHWA initiated a research program to investigate

pile group behavior through carefully performed experiments. First, existing

mathematical models used to design pile groups were identified and evaluated.

From this evaluation, the "hybrid model" was selected and used to analyze a

proposed full-scale pile group to be load tested.

The hybrid model, a

load-deformation model, reasonably predicts load versus settlement, load

transfer patterns, and load distribution to pile heads. The model was especially

helpful in designing the instrumentation system for the full-scale pile group

load test. The field data acquired from the load tests were used to refine the

hybrid method, which led to the FHWA PILGP1 computer program, a modification and

refinement of the hybrid model (see section 2.7.3).

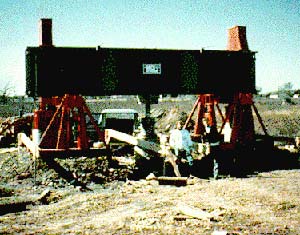

2.7.1 Pile Groups in Clay – To develop the field data

required to verify and refine PILGP1, 11 instrumented steel pipe piles were

driven into a very stiff, saturated, over-consolidated clay soil at the

University of Houston, Texas, campus. The outside diameter of the piles was 273

mm (10.75 in), with a wall thickness of 9.27 mm (0.365 in). The piles were

driven closed-ended 13.1 m (43 ft) deep. Nine piles were driven in a 3 x 3

square array on a spacing of three pile diameters. The two remaining piles were

driven apart from the group to serve as control piles.

Each of the 11

piles was instrumented with full bridge strain gauge transducers and mechanical

telltales to monitor load transfer from the piles to the surrounding soil. Four

of the group piles and one control pile were instrumented with piezometers and

lateral total pressure cells. The surrounding soil also was instrumented with

piezometers and vertical ground movement devices. Electronic load cells measured

applied loads, and settlements were measured at each pile head.

Three-dimensional translations were measured on the massive concrete pile cap

that was suspended off the ground.

The load testing program consisted of

11 compression and 6 uplift (tension) tests, all of which were carried to

ultimate failure loads. The control piles were load tested in compression at

three time intervals to study the effect of soil setup. Each control pile also

was tested in uplift. The nine-pile group (figure 11) was tested in compression

atthree time intervals to assess setup characteristics of the group. Four of the

group piles were tested in uplift; however, these tests were preceded by

compression tests on two smaller groups of four and five piles. The five-pile

subgroup was formed by cutting away the four corner piles, leaving the four edge

piles and the center pile. The four-pile subgroup was formed by removing the

center pile (8,9).

FIGURE 11. Pile group load test in clay.

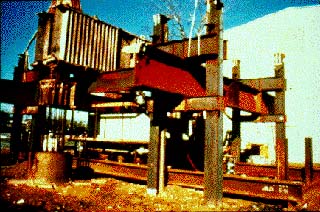

2.7.2 Pile Groups in Sand – A second pile group load test

study was performed on a group of eight timber piles in sands at the Locks and

Dam No. 26 near Alton, Illinois, as part of an evaluation of several

rehabilitation schemes for the distressed locks and dam structures. The timber

piles were instrumented to measure load transfer and deformation up to and

including the failure load. The acquired field data were used to evaluate and

refine the PILGP1 program (16).

The third pile group study involved load

testing five single piles and a group of five piles in sand at a test site in

Hunters Point, California (figure 12). The load test results were also used to

evaluate PILGP1 and a simplified procedure developed under previous studies of

the behavior of single piles and pile groups. Data were obtained on the

comparative behavior of piles of different types with the same relative

geometry. Residual stresses, load transfer, and load-settlement characteristics

were measured and used to evaluate the effectiveness of the new pile design and

analysis procedures. An isolated control pile and three of the five group piles

were fully instrumented, to obtain the load-response data for the analysis. Soil

and ground water conditions were evaluated with standard and state-of-the-art

equipment, such as Standard Penetration Test, Dutch Cone, Stepped Bladed Vane,

Dilatometer, and Pressuremeter testing devices (17). Figure 13 shows a closeup

view of the test pile group and two soil instrumentation boreholes.

After

each of the first and third pile group load test studies, a pile group

prediction symposium was held to discuss the test results and evaluate the most

popular pile group design methods in use at that time (18,19,20).

|

| |

|

FIGURE 12. Reaction frame for pile group |

FIGURE 13. Instrumentation bore holes |

2.7.3 Predictive Model for Pile Group Design and Analysis

(PILGP1) – A comprehensive computer-aided design method called

PILGP1 was developed for FHWA at the University of Houston for the design and

analysis of pile groups. It is a load deformation model that predicts load

versus settlement behavior, load transfer patterns, and load distribution to

pile heads. The model designs the pile group as an interactive element rather

than as a collection of individual piles requiring an adjustment factor. It was

developed from the results of the first full-scale field load test program on

single piles and pile groups. Two additional full-scale field load test programs

were later completed to further refine and validate the computer model. The

current version of the model (PILGP2) is being tested by several consulting

firms, States, and Federal agencies. Continued testing, evaluation, and

refinement of the model is currently under way.

The development and

verification of PILGP1 was based primarily on the full-scale field tests of pile

group behavior under both working loads and failure conditions. Because of the

many variables involved, numerous full-scale field tests needed to be conducted

to provide a statistically meaningful data base. However, the costs involved in

full-scale field testing significantly restricted the number of tests that could

be conducted. The alternatives to full-scale field testing are model field

testing, laboratory model studies, and centrifuge model testing.

2.7.4 In-Service Monitoring of Pile Groups – The three full-scale pile group load tests to failure produced very accurate and valuable data; however, they were very expensive to conduct. In addition to the pile group load tests to failure, four full-scale field projects were initiated with FHWA research funding to observe pile group behavior under working loads. The short- and long-term behavior of the in-service piles was compared with analytical predictions made by PILGP1.

One of the projects was located on the Natchez Trace Parkway (NTP) in

Mississippi, where a pile-supported bridge abutment was instrumented to obtain

load transfer data on a group of six steel piles (12 HP 53) in soft clay and

silt. Samples of load/settlement curve data are shown in figure 14. Another

project was located at Fort Belvoir, Virginia, where soil and pile conditions

were similar to those at the Mississippiproject. Instrument readings were taken

weekly during the first year at each site, monthly during the second year, and

quarterly for several years.

The third site, at the Mocks Bottom

over-crossing in Portland, Oregon, near Swan Island, is underlain by a thick

compressible clayey silt deposit. High down-drag loads were expected because of

the approach embankment loads on the compressible soil. A bitumen coating was

used to reduce down-drag loads by about 90 percent. Although the bitumen-coated

piles cost about 15 percent more than the uncoated piles, fewer piles were

required. Pile instrumentation included settlement and load transfer

monitoring.

The fourth site was located at the West Seattle Freeway in

Washington where a group of twelve 310-mm- (12-in-) diameter concrete piles

supports a pier in medium-dense sands. The bridge pier and pile cap were

instrumented to measure the amount of load transferred to the pile cap, and each

pile was instrumented to measure load transfer from the pile cap to the top of

the piles. Three piles were instrumented for load transfer along the entire pile

length of 30.5 m (100 ft).

2.7.5 Model Testing – The high cost, measured in both time

and money, of obtaining high quality datafrom full-scale load tests on single

piles and pile groups, led to the FHWA staff study to determine if accurate data

could be obtained by conducting model tests in simulated ground conditions.

Using carefully controlled large test pits located at FHWA's

Turner-Fairbank Highway Research Center (TFHRC), more than 200 model tests on

single piles and pile groups have been completed on several different types of

piles in sand and clay soils. These data are being compared with the carefully

controlled centrifugal and full-scale single pile and pile group load test data.

This work is continuing as more variables are studied, and results are entered

in the load test data base to be used for verifying and refining the PILGP1

model.

An investigation of scale effects is an important part of this

study to determine if the model test data can be productively correlated with

the load test data of the full-scale field tests. The establishment of

appropriate scale factors allowed more model tests to be substituted for

expensive full-scale tests. Small-scale models permit numerous parametric

studies at a reasonable cost, and allow soils and other conditions to be

carefully controlled.

The first series of laboratory model tests was

patterned after the timber pile field study at Alton, Illinois. The sandy soil

at the Alton test site was matched as closely as possible at TFHRC. Model load

tests were run on single piles and pile groups (figure 15) at 1/20, 1/15, 1/10,

and 1/3 full scale. As a minimum, three load tests were performed for each

scale. Each pile was instrumented with strain gauges to measure load

transfer.

FIGURE 15. Load test on small-scale model pile group in test tank.

The second series of laboratory model tests was patterned after the full-scale load test on steel pipe piles in clay. Model tests were run at 1/15, 1/10, 1/6, and 1/4 full scale. The laboratory model tests on the 1/20, 1/15, and 1/10 scales were performed in a steel tank 1.5 m (5 ft) in diameter and 1.5 m (5 ft) deep. Because the 1/6, 1/4, and 1/3 scale models were too large to be tested in the laboratory test mold, outdoor test pits were constructed at the TFHRC site (figure 16). The third series of tests was patterned after the full-scale pile group load test to failure at Hunters Point, California.

FIGURE 16. Load test on large-scale model pile group in test pit.

The scaling factors identified in this study were used to establish relationships between load deformation behavior of reduced-scale and full-scale piles and pile groups. These small-scale tests provided a significant amount of data to validate PILGP1 at less cost than full-scale field testing.

2.7.6 Centrifuge Model Testing – Small-scale models permit

parametric studies at reasonable cost and allow soils and other conditions to be

carefully controlled; however, it is difficult to achieve similitude between

corresponding stresses and strains in the model and prototype. The response to

load of a small pile and a large pile cannot be modeled by any simple, direct

relationship derived by ordinary dimensional analysis. The question of scale

effects must be resolved before any useful relationships for pile design can be

developed.

Models of large, heavy structures where gravity is a principal

loading factor are not effective indicators of prototype behavior because the

state of stress in the model caused by self-weight will be much lower than in

the prototype. If the model can be placed in an artificially high gravitational

field, the state of stress limitation can be counteracted almost entirely. A

centrifuge apparatus provides the necessary accelerated gravity rate to load

test the model under simulated gravitational forces. However, to accurately

measure stresses and strains, the centrifuge must be able to accommodate a model

that is large enough to handle the required instrumentation. The larger

centrifuge capacity provides more accuracy in direct modeling of large prototype

structures. A pilot study validated the feasibility of using centrifuge

techniques for corroborating the PILGP1 mathematical model.

In a larger

study, the centrifuge was used to test models of the full-scale pile groups that

were load tested to failure in the previously described field studies. The

combination of centrifuge model testing and small-scale laboratory testing of

conventional models at TFHRC provided valuable physical data to establish

relationships between pile groups of varying scales in the same

environment.

The larger, more comprehensive centrifuge testing program on

single piles and pile groups was performed in sand and clay soils. The results

were used to test and verify assumed similitude relationships between scaled

models and full-scale prototypes. The load deflection and load transfer data

were used to predict full-scale performance and compared favorably with both

measured results and predictions made by computer generated results. The

experimental procedures developed and the verification established in the

program has encouraged the investigation of the many factors that influence pile

performance under controlled laboratory settings. The centrifuge technique

should also be useful and very cost-effective in establishing the predicted

behavior and the sensitivity to design changes of pile foundations for large

projects (21).

2.7.7 Lateral Loads on Pile Groups – Several analysis and

design methods for pile groups under lateral loading have been proposed, but

none had been validated using carefully performed field experiments on

full-scale structures. The theory of elasticity and a number of "efficiency"

formulas often were used as analytical methods for lateral load design. One of

the most promising methods is called the Poulos-Focht-Koch (PFK) procedure. This

method was evaluated through field load tests. Data from the load tests also

were used to develop an improved method of analysis.

The main objectives

of the field load tests were to provide high-quality field data on the

performance of a full-scale pile group under lateral loading and to compare

measured response with that predicted by the PFK method. The load test was

performed at the FHWA pile group test site at the University of Houston, Texas,

campus using the same piles and some of the instrumentation used in the vertical

load tests previously described.

The results of these tests were also

evaluated under a cooperative study with the U.S. Army Corps of Engineers that

was performed at the University of Houston site. After the lateral load tests in

clay were completed, the researchers replaced the top 3 m (10 ft) of clay with

sand backfill and repeated the load tests. The test results were used to refine

and validate the predictive models (22).

2.7.8 Publications and Implementation Items – Research and development activities for pile group foundations were very successful. Numerous quality reports were generated from an unprecedented program of research into an area where few have ventured and none to the same extent. Textbooks and specification codes have incorporated the results of these tests, and the state of the art was advanced significantly.

2.8 Drilled Shafts

A drilled shaft is a machine-excavated circular hole in soil and/or rock that

is filled with concrete and reinforcing steel to support heavy structural loads

in single or multiple units. Vertical loads are resisted by both the base area

of the shaft and in side friction which can be very significant because the

concrete is cast wet and cures directly against the soil forming the walls of

the borehole. They are sometimes socketed in rock, and steel casing is sometimes

required for hole stabilization that may or may not be removed. Horizontal load

is resisted by the shaft in horizontal bearing against the surrounding soil or

rock.

Drilled shafts have many advantages that set them apart from piles

and spread footings. In fact each foundation element has certain pros and cons

that have to be weighed one against the other when deciding on which system to

use in a particular design situation. Each system also has several disadvantages

that have to be evaluated for each design situation. To give confidence as to

performance with respect to the intended task, any foundation element requires

both a reliable method of construction and a standard to define acceptance after

construction.

In this regard, drilled shafts were considered to be less

reliable than others because of the uncertainty of the effects of construction

on the actual service behavior, and the limited knowledge of either reliable

quality-control tests to locate and evaluate defects or inexpensive load test

procedures. Even if there are only occasional failures, they highlight the

variables and unknowns present when working underground, particularly in

water-bearing and potentially caving soils. This results in a lower risk

tolerance for a single or double shaft supported pier compared with multiple

pile supported foundations.

Because drilled shafts for many design

situations offer higher capacities with potentially better economics than driven

piles, the FHWA has spent considerable time and money in research and

development of improved design and construction guidelines for drilled shafts.

Other advantages include less noise and vibration during construction and the

ability to go very deep to avoid scour problems. A major research program was

designed to evaluate existing nondestructive testing techniques for identifying

defects and/or results of adverse downhole conditions that impact the load

transfer/settlement behavior of drilled shafts. It was also planned to develop

rational acceptance criteria for defective drilled shafts on the basis of

quality control during construction, plus a field test program to verify the

research findings that included a search for more economical methods to test

shaft capacity with and without defects.

2.8.1 Nondestructive Evaluation (NDE) of Drilled Shafts – In July 1988, FHWA initiated a contract research study to examine drilled shafts for the effect of defects on performance, and to develop acceptance criteria for use by construction engineers to accept, reject, or modify a newly constructed drilled shaft. The study included the construction of 20 drilled shafts with and without defects for different soil sites located in California and Texas (figure 17). The shafts were constructed using different techniques: dry construction, and wet construction using drilling water, controlled bentonite slurry, and controlled polymer slurry. Five instrumented shafts were statically load tested (figure 18) to determine the effect of the man-made defects on shaft performance, and all shafts were dynamically load tested to correlate with static results. All shafts were tested non-destructively using both surface reflection and direct transmission techniques to determine their effectiveness in identifying defects and/or the results of adverse down-hole conditions that impact the load/settlement behavior of the shafts; results were summarized and evaluated in the report. The allowable defect criteria developed consider the design basis, the ratio of design stress to a maximum code allowable, the type of stress, the level of quality control, and the risk tolerance.

FIGURE 18. Vertical load test of defective drilled shaft.

In addition to the establishment of acceptance criteria, a rating guideline for implementing special integrity testing and a decision tree were developed to guide the engineer or decision maker through construction of a drilled shaft project that includes nondestructive testing. The report also includes detailed information on four promising low-strain NDE techniques (sonic echo, impulse response, cross-hole sonic logging, and gamma-gamma logging), which can be used as part of the quality control procedure, plus information on three alternative load test procedures that show high potential for being economical substitutes for expensive static load tests (see section 2.10).

The sonic echo (SE) and impulse response (IR) test methods use impact energy

applied to the top of the shaft to generate energy waves down the shaft and

return to a receiver that measures the vibration response. These methods are not

able to locate deep defects and they aren't able to detect the size and location

of the defects. Smaller defects lying below a larger defect are easily masked

from above. Cross-hole sonic logging (CSL) and gamma-gamma logging (GGL)

overcome these problems by being downhole methods that pass ultrasonic or

radiation waves through the concrete between source and receiver probes in a

water-filled tube or hole pair as the probe cables are pulled from the bottom

back to the surface over a depth measurement wheel. These methods test the

quality of the concrete lying between a pair of tubes. Four tubes installed in a

shaft before concreting gives sufficient coverage to adequately inspect a shaft

for defects. Figure 19 shows an end view of a rebar cage with four NDE access

tubes.

Results clearly show that the CSL method is superior. The GGL

method requires a radiation source and requires PVC tubes because steel is not

compatible with the radioactive materials. This method is also sensitive to

defects close to the test tubes, and doesn't have the same range away from the

installed tubes that CSL has. In addition, CSL is generally much faster to

perform and does not use radioactive materials (23). Figure 20 shows a

technician performing a surface deflection test on one of the defective

shafts.

FIGURE 19. Instrumented drilled shaft showing man-made defect and NDE access tubes.

FIGURE 20. Low-strain impact test with instrumented hammer and geophone sensor.

2.8.2 Drilled Shafts in Intermediate Geomaterials – Current

design methods for drilled shafts in soil or competent rock are reasonably

well-founded; however, comparatively little effort has been expended to

determine design parameters for intermediate materials such as shales,

claystones, and marls. In September 1991, FHWA signed a second contract to

develop, test, and recommend criteria for determining appropriate exploration,

in-situ testing, and the necessary inputs to the load transfer function or other

design methods for drilled shafts in intermediate geomaterials.

The

contract consisted of essentially three tasks:

Data were collected from projects in Australia, Georgia, Texas,

Massachusetts, and Kentucky. These data have been used to develop the criteria

for exploration and sampling of soil materials to use for developing new load

transfer functions for the design of drilled shafts in shales, tills, and other

materials between soils and hard rock. A field test program was also designed to

validate the new design methods (24).

2.8.3 Free Fall of Concrete in Drilled Shafts – This study

developed information and data that were used to justify increased depths of

free-fall placement of concrete into properly constructed clean and dry shafts

without meaningful loss of strength or segregation of the concrete aggregate.

The report of findings has had a significant economic impact on the drilled

shaft industry.

Prior to this study, the question of whether the

free-fall of concrete over long distances adversely affects the concrete

strength and integrity in drilled shafts persisted in the minds of many

engineers and construction inspectors. This question persisted despite past

efforts to answer it and dispel the concern that concrete does not segregate

during free-fall at any height, and that free-fall placement can be accomplished

without adverse effect on the concrete.

To accomplish the research goals

in a cost-effective way, four 18-m- (60-ft-) long, 0.9-m- (3-ft-) diameter

shafts evenly spaced and tangent to a central 1.5-m- (5-ft-) diameter access

shaft were constructed. The four test shafts were divided into six 3-m (10-ft)

sections with one of four different concrete mixes placed in each section. The

slump, maximum aggregate size, and placement procedures were also varied. The

low slump mixes were also placed with and without super plasticizer. The three

placement procedures were free-fall central drop with careful control to be sure

that the concrete didn't strike the rebar cage, free-fall sloppy drop with

effort actually made to see that the free-falling concrete did hit the rebar

cage, and tremie placement with a tremie pipe extended all the way to the

concrete placement level.

The results of the research were very

conclusive and positive. Construction codes have been changed in many cities,

counties, and States, accordingly. More specifically, the results were as

follows:

None of the lifts placed by central drop free-fall procedures

within the research program exhibited any signs of aggregate segregation. The

design strengths of all centrally dropped lifts varied from 13 percent less to

20 percent more than the reference cylinder strengths. All of the strengths were

well above the intended design strength.

Due to the small variation in

the compressive core strength and lack of aggregate segregation, no definitive

effect of slump, aggregate size, height of drop, depth of fluid pressure, or

addition of super plasticizer was discerned.

Surprisingly, in six out of

seven direct comparisons made between sloppy drop and central drop placement

procedures, the sloppy drop methods actually resulted in higher average

compressive core strengths than equivalent central drop procedures. Also, no

segregation of aggregate was noted for any of the sloppy drop mixes placed.

Thus, on the basis of this research, it is concluded that striking the rebar

cage or the side of the shaft does not have a detrimental effect on the strength

or integrity of the concrete.

Due to the high strengths and lack of

segregation that were apparent in all of the sloppy drop lifts, the effects of

aggregate size, slump, height of drop, height of fluid pressure, and addition of

super plasticizer did not appear to affect the results in a meaningful way for

the well-designed concrete mixes. Even though sloppy drop procedures were not

found to affect the strength or segregation of the concrete, it is not intended

that contractors should begin to place concrete in a haphazard fashion. The

sloppy drop procedure adversely affected the placement of the rebar cage and

also caused additional concrete contamination as a result of traveling down the

soil sides of the shaft. In all cases, the shafts were fully formed and no

honeycombing, voiding or exposed rebar was evident (25).

2.8.4 Load and Resistance Factor Design of Drilled

Shafts – In early 1997, FHWA co-funded a research study on

"Resistance Factors for Drilled Shafts with Minor Defects" with the Association

of Drilled Shafts Contractors (ADSC) and a number of SHA's including California,

Florida, Illinois, Minnesota, Montana, North Carolina, Pennsylvania, and South

Dakota. The objective was to develop design techniques to account for

sub-detectable minor defects that can occur during construction. The analytical

study and most of the experimental work was done by the University of Houston at

its National Geotechnical Experimentation Sites (NGES) facility. Some of the

future testing will be done by FHWA staff at the TFHRC.

It is proposed to

derive resistance factors (or "workmanship factors") for drilled shafts through

analytical modeling that will be calibrated by performing field loading tests to

structural failure on drilled shafts with selected defects. The load testing

will primarily be lateral because the loss of moment resistance in the lateral

mode of loading is potentially more severe than loss of axial capacity for

drilled shafts with steel percentages normally used in highway bridge

construction.

A computer program called LPILE Plus was modified to

perform accurate and realistic modeling of the influence of minor defects on

drilled shaft behavior. The modified version allows for the development of an

independent stress-strain curve within the defect area. It also allows for a

reduction in the tensile strength of both the defective and nondefective

portions of the shaft section. A defect may be located in either the compressive

or tensile portion of the shaft. It is also possible to include more than one

defect in the same section. Six field lateral loading tests were conducted to

verify and calibrate the modified LPILE model.

Lateral load tests were

conducted by jacking a test shaft against a reaction frame consisting of a wide

flange steel girder supported by two reaction shafts. A manual jacking system

was used to jack the test shaft against the reaction frame. Loads were measured

with a load cell and dial gauges were used to monitor lateral deflections of the

test shafts. All test shafts were constructed under wet conditions using a

polymer slurry.

The test shafts were then extracted and examined

carefully to determine the location of the plastic hinges, and to caliper the

exact dimensions along the shaft axes. The results of the load tests will be

used to verify or to calibrate the modified version of LPILE. This modeling will

be eventually used to develop recommendations for resistance factors for drilled

shafts under combined axial and lateral loading. Preliminary recommendations

will be developed in this phase of the research, while more general and refined

recommendations will be developed in the following phases if the results of the

preliminary phase justify further study.

Because typical drilled shaft

defects are usually found at the boundaries between soil and concrete, they can

have effects on both the structural performance of the drilled shafts and the

soil-structure interaction. To isolate the effect of the structural defects from

the variation in the soil resistance, structural laboratory tests will be

conducted on slightly defective shafts out of the soil at the TFHRC, if the

preliminary field test results appear to justify the effort. The results of this

testing program will also be used to verify the method in the modified version