|

CHAPTER THREE |

Relatively few options are available in choosing the ground materials and

site conditions that must be accounted for in the design of highway projects.

The project must be constructed under the conditions that are present at the

particular site; minimal disturbance to existing elements of the roadway is also

a key control factor in the selection and design of the rehabilitation or

reconstruction scheme. For example, the widening of existing roadways or bridges

requires that the selected technique be one that can deal with the problem soil

condition effectively, and also cause minimal damage to the existing

facility.

This is especially true for roadway widening projects in areas

of very soft foundation soils. If the existing embankment was placed in an

excavated trench where the unsuitable material was removed, the same

construction technique will cause serious problems because excavation adjacent

to the existing embankment will jeopardize the stability of the existing

facility. In those cases where the foundation soil is not removed, the pressure

of the widened embankment causes significant differential settlements if the

soft soil is not reinforced or otherwise strengthened.

The problem of

economically constructing and maintaining stable slopes within limited

right-of-way is a continuing concern. Where increasing traffic requires the

addition of lanes within the same right-of-way, costly conventional earth

retaining structures are often necessary. Such structures are also required

where existing or proposed slopes are unstable and flattening of the slope is

not feasible.

In urban areas where depressed freeways are to be widened

or in rural areas where large cut slopes are to be reopened, the slope

excavation can become a very difficult and expensive engineering problem to

resolve. Innovative methods to stabilize or otherwise strengthen the existing

slope prior to excavation must be identified and evaluated to increase the

available inventory of design approaches that can be used to solve these

particular problems.

In recent years, some of the most noteworthy

advances in geotechnology have been in the area of earth reinforcement.

Powerful, innovative techniques have been initiated and are still being

developed here and abroad that have the potential for improving stability at

reasonable cost. However, it should be noted that throughout their short

history, commercial and technological innovations in ground improvement

technology have almost always preceded research studies of fundamental

performance and the development of engineering guidelines. Examples include:

reinforced earth, micro piles, tieback anchors, and soil nailing. Some of the

techniques under study were proprietary, and information on many of the

innovative methodologies was not widely distributed. Therefore, there was an

urgent need to collect, evaluate, and disseminate the current state of the art

on their use and applicability.

To encourage widespread use of these

systems, two pressing questions needed to be answered: (1) What new systems were

available? and (2) Where will they provide satisfactory performance at a cost

savings over conventional methods?

In the past, conservative thinking in

the highway field hindered innovative development and cross-fertilization of

special ground improvement techniques between the United States and foreign

countries, particularly western Europe and Japan. Innovations from these other

countries have fostered major changes in the United States in many areas of

ground improvement and earth retention systems. These changes have occurred in

both our approach to design and construction activities. They are good examples

of how foreign innovations have shaped U.S. practice.

![]()

3.1 Background

At the time this research project was initiated, hundreds of miles of

existing highways were scheduled to be reconstructed or upgraded in areas where

difficult soil and foundation conditions would be encountered. In many cases

there was considerable pressure applied to minimize the disruption to traffic

flow, and to select courses of action that did not require destruction of or

harmful effects to existing pavement systems or structural facilities such as

bridges and retaining walls that still had a long useful life

remaining.

Ground improvement techniques were found to provide benefits

in the following five major areas:

3.2 Objectives

The objectives were to identify and refine existing ground improvement techniques that can be used to stabilize or reinforce soil or rock masses that provide support for roads and structures. Design and construction guidelines were to be developed to reduce costs associated with providing adequate ground support for pavements, bridges, and retaining walls.

3.3 Scope

Research and development efforts in this project were directed toward

analyzing and improving existing techniques for reinforcing and strengthening

ground masses supporting or otherwise impacting highway facilities. The

development of new techniques to replace or supplement existing techniques was

also considered where appropriate. The utilization of ground improvement methods

for the design and construction of new highways was covered; however, the main

emphasis was on the bridge rehabilitation/replacement program and the roadway

restoration program.

This project included all materials and methods to

reinforce, stabilize, or otherwise improve soil and rock masses used to support

highway structures. The project evaluated the basic mechanisms underlying each

technique and developed rational design and construction methodologies for each

appropriate technique.

Design guidelines were developed for each

technique and included the selection of design values and the determination of

geotechnical design parameters, specifications and special provisions, and

system geometrics such as spacing, depth of treatment, equivalent diameters,

sizes, shapes, and weights. Other engineering considerations, such as effect of

groundwater table location, energy attenuation with depth, effective compaction

depth, and types of soils most suitable to each type of improvement technique,

were also studied and appropriate guidance was provided.

Construction

guidelines, including construction control and performance monitoring methods,

were also developed for each technique. Units of measurement and payment and end

product evaluation techniques were also developed and presented in a guidelines

format.

Although the main emphasis was on existing techniques rather than

developing new techniques, it should be noted that many of the existing

techniques evaluated were very new and still in their infancy in terms of

technical development and implementation. Some of these methods demonstrated

significant savings over conventional methods and showed great promise for even

larger cost savings when improved guidelines were developed under this

program.

3.4 Project Description

The major research efforts were in two tasks:

3.5 Soil Reinforcement

Inclusions have been utilized since prehistoric times for the improvement of

soil. The use of straw to improve the quality of adobe bricks dates back to

earliest human time, when many primitive people used sticks and branches for

reinforcement of mud dwellings. During the 17th and 18th centuries, French

settlers along the Bay of Fundy in Canada used sticks for reinforcement of mud

dikes. Some other early examples of man-made soil reinforcement include dikes of

earth and tree branches, which have been used in China for at least 1,000 years

and along the Mississippi River in the 1880's. Other examples include wood pegs

for erosion and landslide control in England, and bamboo or wire mesh, used

universally for revetment erosion control. Soil reinforcement can also be

achieved by plant roots.

Retaining walls are an essential element of

every highway design. Retaining structures are used not only for bridge

abutments and wing walls but also for slope stabilization and to minimize

right-of-way required for embankments. Not many years ago retaining walls were

almost exclusively made of reinforced concrete, and were designed as gravity or

cantilever walls. Such walls are essentially rigid structures and cannot

accommodate significant differential settlements. With increasing height of soil

to be retained and poor subsoil conditions, the cost of reinforced concrete

retaining walls increases rapidly.

Reinforced soil walls and slopes are

cost-effective soil retaining structures that can tolerate much larger

settlements than reinforced concrete walls. By placing tensile reinforcing

elements (inclusions) in the soil, the strength of the soil can be improved

significantly such that the vertical face of the soil/reinforcement system is

essentially self-supporting. Use of a facing system to prevent soil raveling

between the reinforcing elements allows very steep slopes and vertical walls to

be safely constructed. In some cases, the inclusions can also withstand bending

or shear stresses, thus providing additional stability to the system.

At

the time of this research, there were no uniform standards for these systems,

and in fact, there were different design and construction criteria and

procedures for each system. Moreover, each of these systems had a different

performance record. Research under this project identified and evaluated various

reinforcement methods such as tensile, compressive, and shear force resistance

elements that are inserted into the soil mass to improve bearing capacity and/or

settlement characteristics. The evaluations included all materials and methods

to reinforce soil masses. Studies were undertaken to evaluate the basic

mechanisms underlying each technique, and rational guidelines for design and

construction of each technique were developed. Each technique was evaluated by

reviewing the literature, and discussing the performance of particular case

history examples with design and construction engineers, plus specialty

contractors involved in using these innovative techniques.

Subsequent

studies involved soil characterization and reinforcement material evaluations to

determine appropriate parameters for design and construction control.

Small-scale laboratory model and also centrifuge model studies were conducted

for those techniques that required further refinement and verification.

Full-scale field testing and construction monitoring studies were also done to

validate some of the research findings from the initial investigations.

3.5.1 NCHRP Benchmark Study – The FHWA research program in soil reinforcement was based on the results of a major NCHRP study that performed an extensive literature review and evaluation of available systems and design methods (NCHRP Publication 290). That state-of-the-art report provided in-depth background on soil reinforcement for engineers seeking an understanding of this important, and at that time, new subject.

3.5.2 Reinforced Soil Structures – The NCHRP study was

expanded by FHWA to examine the design, construction, and performance aspects of

a selected few of the mechanically stabilized earth systems identified in Report

290 for use in retaining structures and excavation support systems. The main

purpose was to develop guidelines for these systems to provide highway engineers

with guidance for selection, design, and construction of the selected systems in

a generic manner.

The study was performed by reviewing and evaluating

several existing methods in terms of field experience, laboratory testing

(including centrifuge studies), analytical studies, and a full-scale field

evaluation program (figure 27). The results were then used to develop and

substantiate the generic design procedures and other guidelines presented in the

manual (32). Volume 2 contains a technical summary of the research supporting

theory to verify the design theory in Volume 1, plus information on several

proprietary reinforced soil systems (32).

FIGURE 27. Reinforced soil test wall.

The manual has become a valuable tool to assist highway engineers and others in determining the feasibility of using reinforced soil systems for walls and embankment slopes on a specific project, evaluating different alternative reinforcement systems, and performing preliminary design of simple systems. The manual also provides a basis for evaluation and preliminary design of new earth reinforcement systems that may be proposed in the future.

3.5.3 Reinforced Soil Foundations (RSF) – A staff study at

TFHRC investigated the use of geosynthetic reinforcing elements beneath spread

footings to create a composite material with improved performance

characteristics to determine if this method of ground improvement is applicable

to bridge support. Information was obtained on how to quantify the improvements

and optimize the location of the reinforcement in the soil below the footing.

The results of this study proposed an optimal size of an RSF using soil strain

signatures and normalized settlement criteria. Model load test results on 34

footings describe the optimal depth and reinforcement layering within an

RSF.

One of the first tests conducted was on a spread footing placed at

the surface on an unreinforced compacted sand that was load tested to failure

(figure 28). Both the footing and surrounding soil were fully instrumented to

map the distribution of soil strain beneath the footing. The map was used to

describe the complete mode of soil failure, and clearly defines the zone of

maximum soil displacement. The identity of this zone within the engineered fill

pin pointed where the geogrid should be placed for optimum reinforcement in the

next series of tests.

FIGURE 28. Spread footing load test on reinforced soil foundation.

The next series of tests was conducted to evaluate the relationships between

the layering of the reinforcement to the width (B) of the spread footing. Two

series of load tests were performed on four different sizes of square footings

(0.3 m, 0.45 m, 0.6 m and 0.9 m) on the sand surface to measure the

settlement(s) of the footing at various loads.

The next tests were

performed to compare the performance of Reinforced Soil Foundations (RSF's) to

the unreinforced footings with various embedment depths (D) to determine the

best features of each approach to increase bearing capacity. For example, a

spread footing embedded 0.5 B was compared with a one-layer RSF placed at 0.375B

beneath the base of a surface footing. An embedded footing with a D/B of 1.0 was

compared with a three-layer RSF placed at 0.25B, 0.5B and 0.75B below the

surface footing. The test results were used to calculate bearing capacities at

various D/B ratios.

Vertical displacements within the sand below the

footings were measured by telltales located at various depths below the four

corners of each footing. Horizontal strains were measured by inclinometers

located at 0.25B and 1.0B outside the footing footprints. Linear Variable

Differential Transducers (LVDT's) were used to measure settlement at the top of

each footing for each load increment that was measured by load cells between the

footing and loading jacks. Footing settlement, vertical soil displacements below

the footing, and horizontal displacements to the side of each footing were

measured at each load increment.

As expected, the data show that soil

deformation occurs first in the upper layer of sand just below the footing and

propagates to deeper areas with increasing load, following a pattern that can be

clearly seen in any standard soil mechanics text. What is not shown anywhere

else besides these tests, is the well-defined strain signature that clearly

shows that almost all soil deformation occurs within a zone of 0.5B beneath the

footing, rather than 1.0 to 2.0B, as proposed by previous

researchers.

Because the data show that the upper layer undergoes the

highest strain during the early part of the load test, it is recommended to

place a layer of reinforcement in this zone of initial strain, and a second

layer in the lower zone of maximum strain. The telltale measurements clearly

identified the higher zone to be at 0.125B, and the maximum zone at 0.375B.

Placing a layer of reinforcement at these levels will significantly improve the

load settlement performance of surface or shallow depth footings on sand. If

only one layer is required, it should be placed at the point of maximum strain,

which is approximately at the 0.375B level. It was also noted that, when the

reinforcement was placed in the zone of maximum soil shear, it acted to

significantly inhibit the development of a classical bearing capacity

failure.

The zone of horizontal displacement is mostly within a distance

of 0.5B beyond the edge of the spread footing. This means that the reinforcement

doesn't need to extend more than 0.5B past the edge of the footing on all sides.

The imprint area of the reinforcement is therefore required to be four times the

size of the footing imprint.

In many tests comparing surface footings on

sand to surface footings on an RSF, the ultimate bearing capacity of the RSF was

twice the value of the conventional footing. The performance of an RSF was shown

to be very comparable to the positive effects of footing embedment. The

knowledge gained during these experiments was put to immediate use for design of

the RSF to support the geosynthetic reinforced soil bridge pier described in

section 3.5.4.1 of this chapter.

A review of the literature indicates

that this study was the largest of its kind, both in terms of number of footing

load tests performed and size of footings tested. The results clearly

demonstrate that geosynthetic reinforcement can substantially increase the

bearing capacity of shallow spread footings on sand and can reduce the amount of

settlement, especially differential settlement of the four corners of footings.

The footings resting on unreinforced sand settled unevenly, while those on

reinforced foundations settled very evenly with no tipping of the corners.

Additionally, the footings on a RSF were more likely to experience a gradual

failure curve rather than a plunging failure (30).

3.5.4 Geosynthetic Reinforced Soil Structures – The use of

geosynthetic grids and sheet materials to reinforce soil layers in walls,

abutments, and piers to support highway structures has increased significantly

in the 1990's due to cost advantages and freedom from worry about corrosion and

durability issues. Similar to the rapid increase of other ground improvement

technologies, expanded usage has preceded the development of rational technical

guidelines and fostered significant debate over several technical issues, such

as vertical spacing of reinforcement layers, connection issues, compaction

details, facing cracks, soil fill specifications, seismic response, scour

protection, pre-straining requirements, and optimal applications. It is also

necessary to determine optimum base to height ratios, including appropriate

limitations and design criteria, plus lateral load resistance

factors.

FHWA developed an in-house staff project to answer these

unanswered questions. The first phase of the study involved the construction of

a full-scale bridge support pier out of polymer based fabric sheets, road base

gravel, and regular home building cinder blocks (figure 29). The pier was

constructed at the TFHRC campus to facilitate construction supervision and

monitoring of the research testing. It was built on a reinforced soil foundation

platform that was placed approximately one meter below natural grade.

FIGURE 29. Geosynthetic reinforced soil support pier.

A series of model piers was also built and tested to supplement the results of the full-scale tests. These smaller piers were much faster to construct and easier to test to failure than the prototype, which permitted the researchers to vary different parameters to evaluate the effects of certain changes on overall performance. Another series of full-scale tests on the prototype and several larger full-scale structures is planned for the 1999 construction season.

3.5.4.1 Full-Scale Pier Project – The bridge support

pier was built to a height of 5.4 m and was 3.6 m x 4.8 m at its base, with a

slightly smaller top area due to an inward tapering effect for aesthetic

purposes. The pier was fully instrumented to monitor load, vertical settlement,

lateral deformation, and internal creep and strain in the reinforcing

fabric.

A thin concrete leveling pad was used beneath the facing blocks

to ensure a proper start and level rows of blocks throughout the entire height

of the pier. Six concrete reaction pads were placed on top of the support base

and inside the facing block perimeter. Four steel rods were anchored in each

reaction pad. They were designed to be extended through the full height of the

pier and attached to a similar set of six reaction pads to be placed at the top

of the pier and matched to the bottom pads. The steel rods were isolated from

the internal soil mass to preclude any vertical reinforcement contribution from

the rods. The reaction pads and connecting steel rods were needed to apply

squeezing loads for testing purposes, and were designed not to interfere with

normal functioning of the pier.

A high-strength, woven polypropylene

geosynthetic made by Amoco (#2044) was used to reinforce a well-graded gravel

material that is routinely used beneath highway pavements in Virginia. The

cinder blocks were dry stacked and served as a construction form as well as a

facing block for the gravel during compaction operations. The fabric was placed

at each layer of block and gravel, with no special connection features except to

overlap the fabric between each layer of blocks. No gluing or pinning was used

to secure the fabric to the blocks.

At the mid-height of construction,

the top reaction pads were placed and reaction beams were attached to the steel

rods to squeeze or pre-strain the composite soil mass using heavy duty loading

jacks. Load cells, LVDT's on top and on the sides, and a laser measurement

system were used to monitor stress and strain responses to the squeezing

process. The pre-straining operation served to eliminate most of the expected

post-construction settlements, and enhanced the composite nature of the

reinforced soil mass because the key to the composite feature is the denseness

of the soil and the bond connection between the fabric and the compacted

soil.

The vertical spacing between reinforcement sheets plays a major

role because the composite feature is greatly diminished when separation

distances between reinforcement layers become too large. The optimum spacing

issue was further studied under the model test investigation. The contribution

of the facing blocks is also under investigation. In addition to the facing

aesthetics, soil raveling and erosion control, and construction form work during

compaction, there is a good possibility that the blocks make a significant

contribution to the composite feature of the reinforced mass.

The size of

the reaction pads and the number of steel rods were far greater than necessary

to provide sufficient pre-straining during the construction process at the

mid-point (or one-third point if deemed appropriate) and completion of the

full-height pier. The extra reaction capacity was installed to provide

sufficient capacity for research load testing purposes. No rods or pads would be

needed if pre-straining was not considered important to ensure bearing capacity

and settlement control. For this design, only about half the available capacity

would have been required if load testing to failure was not in the plans, and

pre-straining only was desired.

At full-height construction, the pier was

again subjected to pre-straining. The same stress and strain type measurements

were taken, plus creep and strain measurements were made on four layers of

fabric installed in the top half of the pier. A total of 21 strain gauges was

installed on each of the four layers. The measured strain along each fabric

layer was uniform, indicating the load was applied evenly over the pier

area.

The pier was later load tested to a much higher level than the

pre-straining levels (but less than complete failure load) to determine near

upper bounds on bearing capacity and settlement values for this particular

composite mass. The loading was stopped when severe cracking, bulging, and

displacement of the facing blocks occurred, but not before load and displacement

measurements demonstrated how strong and capable this system is for support of

heavy bridge loads without significant deformations resulting. Maximum loading

conditions were not applied in order to preserve the structure for additional

testing; however, total collapse failure loads were imposed on the smaller scale

models discussed later.

The FHWA manual, Mechanically Stabilized Earth

Walls and Reinforced Soil Slopes Design and Construction Guidelines,

recommends that bridge loads on this type of structure not exceed 200 kPa (2.1

tsf). At this loading level the performance of the pier was very good. Lateral

deformation and vertical settlement were very small and no cracks or other signs

of distress occurred in the blocks. Performance also remained good at much

higher levels than the not to exceed limit specified in the manual.

The

connection strength issue did not seem to be a problem in this situation. The

connection consisted of a frictional bond between the blocks and the fabric,

with no glue or fasteners used to enhance the connection. Results show that none

was needed. The vertical squeezing forces that were applied to the soil and

fabric mass seemed to cause a "drag" type of force to be applied to the blocks

as the reinforced soil mass was forced to consolidate. Compression cracks

occurred as the drag forces reached higher levels; however, the connection issue

was not adversely affected.

The overall experiment was very successful

and served to increase our knowledge of how this type of structure can best be

utilized to provide safe and efficient support for highway bridges, especially

in remote areas where concrete and steel are expensive to haul to the bridge

site, and heavy equipment is hard to mobilize. This concept may also be a good

alternative in seismic areas because each layer of gravel and reinforcement may

serve as a force-dampening shock absorber between the earthquake-generated

ground motions and the bridge superstructure (33).

3.5.4.2 Model Studies – At another site on the TFHRC campus, a series of smaller scale models of the prototype pier were built and tested to failure. The same type of block was used to build the models except that the fabric was not placed to overlap the blocks, and the blocks were removed before testing. A base height ratio of 0.5 was used to provide similitude with the prototype. The same gravel material was used; however, the same geosynthetic reinforcement material was used in only a few of the models at various vertical spacing distances to investigate the effect of distance on the composite mass performance under extreme loads. A lesser strength fabric was also tested at varying spacing distances (33).

3.5.5 Corrosion and Durability – One of the major design

concerns for reinforced soil structures has been the corrosion or durability of

the reinforcing elements in the soil/water environment in which they are placed.

In the early days of building reinforced soil structures in the United States,

the material of choice was almost exclusively metallic, either in strip or grid

configuration. Galvanized steel worked best, and after a short trial period the

use of aluminum and stainless steel was discontinued due to very poor

performance. Concern about corrosion of the galvanized steel prompted some

engineers to try geosynthetic polymer materials as a reinforcement alternative;

however, similar durability concerns soon became apparent because of the lack of

information on degradation factors, such as hydrolysis and oxidation phenomena,

that might occur in the soil/air/water environment below ground.

To

assist engineers in designing new projects and evaluating existing walls, FHWA

performed a series of comprehensive research studies to investigate the

corrosion potential of metallic reinforcing elements and polymer degradation as

related to the design life of the reinforced soil structures. The durability

research included an analysis of the principal aging factors to determine the

extent of decomposition that typically occurs in a soil environment. Other

topics, such as installation damage, biological and environmental attacks, and

creep damage, were also investigated. Two reports were

issued that describe the corrosion process and provide guidance and criteria for

evaluating potential corrosion losses when using coated or uncoated steel

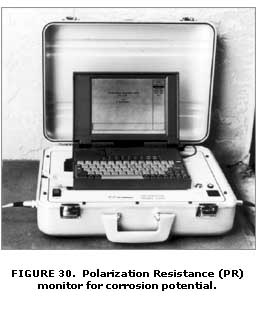

reinforcing elements. Remote electrochemical measurement equipment called a PR

Monitor was also developed to monitor corrosion potential and in-situ corrosion

rates of base or galvanized steel reinforcements on both new construction or

existing walls. The PR Monitor (figure 30) measures the polarization resistance

(PR) of a corroding interface because the corrosion rate is inversely

proportional to the PR (34,35).

Two reports were

issued that describe the corrosion process and provide guidance and criteria for

evaluating potential corrosion losses when using coated or uncoated steel

reinforcing elements. Remote electrochemical measurement equipment called a PR

Monitor was also developed to monitor corrosion potential and in-situ corrosion

rates of base or galvanized steel reinforcements on both new construction or

existing walls. The PR Monitor (figure 30) measures the polarization resistance

(PR) of a corroding interface because the corrosion rate is inversely

proportional to the PR (34,35).

Several reports were also disseminated under the study, "Durability of

Geosynthetics for Highway Applications", that describe the hydrolytic and

oxidative degradation processes, installation damage patterns, and creep

concerns of polymer reinforcements. These reports, plus others in the publishing

process at the time of print for this summary report, provide guidelines and

testing protocols for calculating the appropriate strength reduction factors for

use in design life predictions (36,37,38). Some of the important findings are

discussed next.

On the basis of the data thus far, it appears that most

geosynthetic products have the durability needed for critical reinforcement

applications, especially in relatively neutral soil environments. In severe

environmental conditions, results indicate a fairly wide range of degradation

rates. A test protocol for long-term durability performance testing of

geosynthetics (i.e., oven aging and immersion testing) has been developed, along

with an analytical model for service life prediction of

geosynthetics.

Variations in the test protocols used to chemically

characterize polymers, with specific reference to geosynthetics, which could

significantly affect test results or make test results difficult to interpret,

have been identified and corrections to the protocols were made. These protocol

variations help to explain why comparison and use of data provided in the

literature are difficult.

From the effort to better define the testing

protocols, preliminary standardized test and QC/QA procedures to be applied

industry-wide have been developed. This has set into motion the ability of the

industry to perform the tests that will likely be recommended for future

evaluation of geosynthetic durability, and the ability to develop a consensus on

how those tests should be performed and quality control maintained.

The

polymer and soil environmental factors that affect the geosynthetic degradation

rate have been identified as well as tests that can be used to assess and

quantify these factors. The study has also identified the issues that must be

addressed to develop life prediction models for geosynthetics, especially with

regard to relating the laboratory environment to the in-soil environment. A

technology transfer report was developed by FHWA's Office of Technology

Applications to assist practitioners in implementing the new guidelines

(39).

A separate but parallel effort by Transportation Research Board

(TRB) committee A2K07 has been initiated to develop the framework necessary for

rapid implementation of the results of this study. This effort has also helped

to identify just where the real needs in terms of geosynthetic durability

knowledge are so that a coherent recommended practice to determine the long-term

strength of geosynthetics can be developed.

The study has created an

environment that has promoted improved communications within the industry, in

particular their polymer experts and suppliers, and with the portion of the

engineering community that routinely uses geosynthetics. This has allowed the

geosynthetic industry to better understand the needs of those who use

geosynthetics regarding durability issues, and has helped geosynthetic users to

know what questions to ask and what can be realistically expected from the

industry. A team spirit between the industry and geosynthetic users, which was

not present before the study began, has begun to develop.

3.5.6 Permanent Ground Anchors (Tiebacks) – Permanent

ground anchored wall systems, often called tieback walls, use tensile elements

anchored in the ground to support earth retaining structures or stabilize

landslides. These walls are built in excavated cuts from the top down. Other

highway applications include bridge abutment underpinning when an end slope

under an existing bridge is removed to permit widening of the roadway; and the

strengthening of existing earth retention structures that have deteriorated

because of corrosion or require additional support for increased loading

situations.

Temporary ground anchors were the first system to be

introduced in the United States to support excavations while the permanent

facility was being constructed. Soon, however, these temporary measures gained

wide acceptance because of economic and safety aspects, and they gradually

became attractive as permanent solutions. The economy results from elimination

of temporary support systems and reduced right-of-way considerations; safety is

improved by eliminating cramped excavation work areas that are cluttered with

delicate bracing.

Permanent ground anchors are relatively new

geotechnical elements that were developed to a large extent by specialty

contractors who had developed their own methods of design and installation. Many

of these methods were proprietary or closely guarded family secrets. SHA design

provisions were viewed by ground anchor contractors as unnecessarily

conservative and restrictive, which increases construction costs.

At

first there was much concern on the part of highway engineers because of a

perceived lack of rational design procedures, construction methods, and

documented performance experience. In response to this need, FHWA researchers

initiated a contract research study to investigate this technology under

experimental conditions to examine stresses and deformations occurring under

typical loading conditions. Results were then used to develop a comprehensive

manual of engineering guidelines and a computerized design procedure

(40).

A series of four model test walls (2 m high and 5 m wide) were

instrumented and tested to failure (figure 31) at the University of Illinois to

verify and refine the preliminary guidelines established in the early stages of

the study on the basis of a literature search and analytical trials. A

full-scale wall (10 m high and 60 m long) was also built to further refine and

validate the new guidelines. The full-scale wall (figure 32) was built at the

NGES facility at Texas A&M University. One section of the wall had only one

row of anchors with heavy soldier beams, and the other had two rows of anchors

with smaller soldier beams. Pullout tests of full-scale, vertically installed

ground anchors were also conducted in an adjacent area at the TAMU clay site

(41).

FIGURE 31. Large model ground anchor test wall.

FIGURE 32. Full-scale ground anchor test wall at TAMU NGES.

3.5.7 Soil Nailing – Soil nailing is an earth retention

system that combines short in-situ reinforcements and shotcrete to support

excavations, hillside cuts, depressed cuts, and embankment steepening. Soil

nailing structures are built from the top down in a minimum of space, without

temporary support, without soldier beams, without disruption behind the wall,

and less disruption to traffic and adjacent construction activities. Soil

nailing structures can be built in cohesive and granular soils or in relatively

heterogeneous soils with small, easily mobilized equipment, with less start-up

time, and in remote sites. Soil nailing walls are often the most effective

solution to the problems associated with emergency repairs, vertical cuts close

to property lines, projects where drilling costs are high, and projects with

limited access. When used in the proper application, a soil nail wall can be

constructed faster and more economically than most other retaining wall

systems.

An in-situ reinforcement technique that improves the soil's

overall stability, soil nailing is constructed with steel reinforcing bars (soil

nails) that are usually drilled and grouted into the ground. Sometimes, other

metal tubes or rods are used instead of bars to resist tensile, compressive, and

shear stresses. A relatively large number of soil nails are installed in a

designed pattern that reinforces the earth into a stable block, which supports

the unreinforced soil behind it in a way that is similar to that of a gravity

wall. Soil nailing structures are designed to be both externally and internally

stable. External stability requires that the structural mass be designed with an

adequate factor of safety against sliding, overturning, and bearing

failures.

To check a structure's internal stability, most engineers use a

method of limit equilibrium analysis that computes the driving and resisting

forces at the critical failure surface. To further the development and use of

soil nailing, FHWA has instrumented many soil nailing structures, conducted

extensive model testing, and thoroughly analyzed prototype walls. As a result,

current designs are more economical and provide for better control of

movement.

Construction of a vertical excavation begins with a shallow

cut. The height of this cut is determined by the soil's ability to temporarily

stand unsupported, normally about 2 m. The next step consists of

shotcreting the cut and installing the soil nails. Once these steps are

completed, another lift is constructed below the first, and the process is

repeated until the desired level is reached. Drainage is provided to remove

water from behind the shotcrete wall. When soil nailing projects are constructed

as retaining walls, construction follows the same sequence, with the addition of

better drainage details and possibly corrosion protection for the

nails.

In nonaggressive ground environments, grout alone provides

satisfactory corrosion protection. When used in more aggressive soils, the steel

nail can be epoxy coated to increase its resistance to corrosion. In most soil

nailing applications, the construction of a separate concrete face is reasonably

economical, as well as aesthetically and structurally superior to the use of

shotcrete facing.

Although soil nailing was imported to the United States

from Europe with reasonably good engineering guidelines, there were some major

questions concerning the general behavior mechanisms, failure modes, durability

aspects, facing design, and seismic behavior. A series of research studies was

initiated to develop comprehensive technical guidelines for using soil nailing

techniques to stabilize highway slopes and excavations. The development of a

computerized design program was also an important associated objective of this

research.

Analytical studies and physical experiments were conducted to

evaluate design parameters such as type of soil and noncompetent rock suitable

for nailed reinforcement; type, size, and location of reinforcing nails; and

design equations for checking stability, internal pullout resistance, and

deformations. Durability aspects were also to be identified and procedures

developed to provide assurances for corrosion protection and structural

permanence. Laboratory tests were conducted to verify the choice of appropriate

parameters for prediction and design. Field tests were then performed on

full-scale structures to verify laboratory and analytical results (42). Figure

33 shows an instrumented nail being installed on a test wall at the Cumberland

Gap tunnel project.

During the course of the soil nailing research

project, a partnership with French researchers was developed to coordinate

investigative efforts. The cooperative project was called "Clouterre", which is

French for "soil nail." As part of the Clouterre agreement, FHWA agreed to focus

major efforts on seismic behavior, field performance monitoring, development of

a research quality data base, and facing design investigations. France placed

most of its emphasis on the analysis of the engineering behavior of soil-nailed

structures in different types of soils, including system behavior and structural

displacements. The French researchers were also responsible for making a

critical assessment of available design methods and special loading conditions,

such as frost effects and surcharge loadings, that occur at bridge

abutments.

FIGURE 33. Installation of instrumented soil nail at Cumberland Gap site.

A study entitled "Seismic Analysis of Soil-Nailed Retaining Structures" was

initiated under joint sponsorship with the National Science Foundation (NSF) to

evaluate the response and possible failure mechanisms of soil-nailed walls under

dynamic loads. A finite element analysis and evaluation of the dynamic loading

behavior of these walls was performed using an integral approach consisting of

post-earthquake observations, centrifuge testing, and numerical analysis. The

researchers developed testing procedures to establish reliable design parameters

for characterizing the dynamic soil-nail interaction and formulated an analysis

procedure for the computation of dynamic loading effects on the location and

magnitude of maximum nail forces.

A series of laboratory model tests and

full-scale field tests was previously completed for FHWA to evaluate soil and

reinforcement parameters that are involved in the design and construction

procedures for soil nailing. Data analysis and evaluation of existing procedures

were used to develop interim design and construction guidelines for using soil

nailing techniques to stabilize soil cutslopes.

In a separate research

study, FHWA funded a project for "Testing of Soil Nail Wall Facings" to

determine ultimate and service capacities for developing an appropriate

facing/connection design, especially in regions of high seismic activity. At the

time of this research, the design methods for facings were quite conservative.

Therefore, it was hoped that this research would allow thinner facings to be

used, resulting in construction cost savings. Also at that time, there was not a

consensus regarding which of the available design methods should be used,

because none of the methods were found to directly apply to soil nail wall

facings. The new procedures are described in the FHWA manual

(43).

Another FHWA study investigated the use of soil nails for cohesive

soil stabilization. A specialized direct shear apparatus was used to test

specimens of the clay reinforced with small-diameter steel bars (nails) to

examine the engineering effectiveness of using soil nails to stabilize

excavations and slopes in clay soils. Proof tests were conducted initially using

sand to verify the performance of the shear test apparatus, measurement

instrumentation, and data acquisition system. Direct shear tests were then

performed on unreinforced clay specimens to obtain reference data under constant

strain rate loadings before the soil-nail reinforced tests were done. Stresses

in the nails during soil shearing were measured to determine the nature of nail

loading. Existing stability analysis methods for nail reinforced soil masses

were verified and modified to account for the measured behavior.

A

full-scale wall was constructed at the UMASS NGES facility in Amherst within the

varved clay layers of soil in a remote section of the site. Two rows of nails

were installed and readings were taken from the strain gauges and tip load cells

on the nails, plus the vertical and horizontal inclinometers and piezometers in

the soil behind the wall face. The wall was then induced to fail (figure 34) by

excavating below the reinforced portion of the wall to undercut its stability.

Instrumentation readings were taken during the excavation operations, and at

failure when the wall was undercut a total of 2.5 m below the reinforced face of

the wall. The field work was funded by FHWA and ADSC.

FIGURE 34. Failed soil nail wall due to undercutting.

FHWA and the Washington State Department of Transportation cooperatively funded a study to collect and develop a world-wide data base of instrumented soil nail wall projects. The study also involved using the data base to evaluate existing soil nailing design methods. The data collection and evaluation/validation of the available limit-equilibrium methods provided an improved understanding of the stress-deformation mechanisms in soil-nailed walls, which in turn led to the development of an improved and well-substantiated design procedure for soil-nailed walls.

3.6 Soil Treatment

The primary concern in soil support for structures is volume stability,

strength and durability. However, adequate support is highly variable and is

more case specific than site specific. In the proper state, virtually any soil

type, except highly organic materials, may be adequate for foundation support.

Conversely, any soil type, in its natural state, may be inadequate for

foundation support. Adequate soil support depends more on the loadings and

performance requirements than it does on the soil itself.

The history of

soil treatment techniques can also be traced back to ancient times, like

reinforcement technology. During the 1970's and 1980's, several promising

technologies were imported from Europe along with the previously described

reinforcement methods, except that they did not require the insertion of

reinforcing elements into the soil mass. Four of these special methods were

selected by FHWA for detailed study and evaluation to better understand the

basic mechanisms underlying each technique; however, subsequent funding

limitations caused the elimination of one of these technologies (grouting) from

the overall program. Research studies were initiated and completed on dynamic

compaction, prefabricated vertical drains, and stone columns.

3.6.1 Stone Columns – As in most new ground improvement techniques that were developed in foreign countries, experience has preceded the development of theory and comprehensive guidelines. Stone columns have been used since the 1950's as a technique for improving both cohesive soils and silty sands. Potential applications include (1) stabilizing foundation soils, (2) supporting structures, (3) landslide stabilization, and (4) reducing liquefaction potential of clean sands. The high potential for beneficial use in highway applications prompted a comprehensive investigation to determine how and why the system works so well, and to develop appropriate design and construction guidelines. The guidelines report describes construction, field inspection, and design aspects of stone columns. Also, several case histories are described. Bearing capacity, settlement, and stability design examples are given in the design appendices (44).

3.6.2 Dynamic Compaction – Dynamic compaction is also a

very cost-effective soil treatment technique that can be used to improve poor

subgrade support conditions at a roadway or bridge site. This is particularly

true in or near urban areas where land with good support conditions has already

been developed or set aside for commercial purposes other than highways. Much of

the remaining space is undeveloped land because of poor soil

conditions.

In many cases new roads and streets are forced to traverse

old landfill deposits, strip mine spoil areas, or building rubble and

construction debris deposits. Naturally occurring loose sands and collapsible

soils such as loess can also present difficult construction problems for highway

engineers. Dynamic compaction techniques have proven to be ideally suited to

handle these problems where other techniques have failed. Another important

application is for densifying loose sands to reduce liquefaction potential in

high-risk seismic zones. Dynamic compaction techniques have been found to

produce densification in natural and manmade deposits to depths varying from 3

to 12 m below grade.

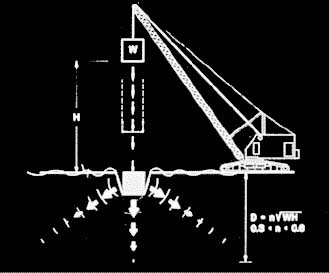

Dynamic compaction is defined as the densification

of loose soil deposits or miscellaneous fill materials by means of repeatedly

raising and dropping a heavy weight from varying heights to impact the ground

(figure 35). This process has also been called by other names, including impact

densification, heavy tamping, dynamic consolidation, pounding, and dynamic

precompression. The energy is generally applied in phases on a grid pattern over

the entire loose or soft area using either single or multiple passes. Following

each pass the craters are either leveled with a dozer or filled with granular

fill material before the next pass of energy is applied.

FIGURE 35. Schematic of dynamic compaction methodology.

All of the energy is applied from existing grade, and the degree of

improvement is a function of the energy applied through the mass of the tamper,

the drop height, the grid spacing, and the number of drops at each grid

location. Lighter tampers and smaller drop heights result in shallower

improvements. For greater depths and higher relative density improvements,

heavier tampers and higher drop heights must be used.

When the technology

was first imported from Europe, little was known about how to plan a project or

complete a preliminary evaluation to determine if dynamic compaction is

appropriate for the specific site and subsurface conditions. Design details and

construction monitoring guidelines were nonexistent. There were no sample

specifications to guide designers, and no procedures were available to measure

the degree of improvement achieved with each pass. Not knowing when enough is

enough can reduce the cost advantages rather quickly.

To gain more

insight, FHWA initiated a contract research study to conduct tests and

evaluation studies of the improvement mechanism to better understand how the

technique worked. A series of field experiments was conducted to investigate

soil and tamping parameters involved in the dynamic compaction process.

Instrumentation was installed to monitor ground vibrations, horizontal and

vertical displacements, pore pressures, acceleration and speed of the tamping

weight, penetration of the weight into the ground, and degree of treatment

achieved.

The results of the field tests were used to develop generic

specifications and a manual that describes in detail all of the design and

construction issues, plus all of the non-technical issues previously mentioned

(45). The manual was recently updated by FHWA's Office of Technology

Applications and reissued as Geotechnical Engineering Circular No. 1 to provide

this new information to assist SHA's with a user-friendly engineering document.

A slide tape show was also developed to provide a visual rendering of the manual

for instructional purposes.

3.6.3 Prefabricated Vertical Drains – The need for proper

drainage in highway projects is well established. Sand and /or gravel layers (or

other geometric shapes) have been used for decades to provide the appropriate

drainage vehicle. One of the most cost-effective methods of soft ground

improvement is through drainage, especially the use of radial drainage and

manmade vertical drains working in tandem. When heavy embankments are placed on

soft depositional type soils, the loading will tend to squeeze the water out of

the soil in a vertical upward direction to a drainage blanket placed at the

bottom of the embankment, and possibly downward to a natural drainage layer (of

sand) that might exist below the soft and low permeability layer that is being

squeezed.

In a soil that has been deposited in layers in ancient times,

the boundaries between layers tend to impede the water flow vertically.

Therefore, the horizontal permeability is significantly faster, and can be as

much as 10 times faster if there are intermittent granular layers in the

deposited soil. By installing artificial vertical drains, the drainage path is

greatly reduced and horizontal permeability will control the time of

drainage.

When water is drained, the soil consolidates and gains

strength, which increases its ability to safely carry more embankment loading,

which will cause more consolidation and so forth. Very high embankments can thus

be constructed in stages with time delays to allow for consolidation and

strength gain.

Until recently, sand drains have traditionally been used

for this purpose with success; there are, however, a number of practical

constraints associated with installing sand drains, namely, the disturbance of

soil (smear) around the sand drain, the need for a large quantity of water when

jetting is used, the availability of quality sand to fill the drains, and the

relatively high cost of installation. Because of these

disadvantages, engineers searched for a better way to create these artificial

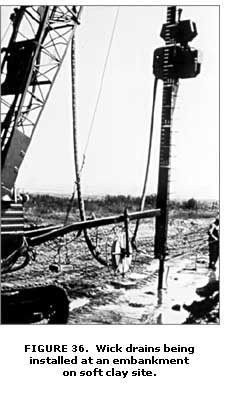

drainage paths that would be cheaper, faster, and environmentally less

disruptive. The most popular alternative was called a "wick drain" and consisted

of a prefabricated plastic band that had a geosynthetic filter fabric wrapped

around a central plastic core that the water moved through after it was filtered

through the wrapping (figure 36). Although these wick drains had many

significant advantages over sand drains, there were many unanswered questions

regarding design assumptions, laboratory screening tests, quality control,

installation methods, durability, and generic acceptance specifications.

Because of these

disadvantages, engineers searched for a better way to create these artificial

drainage paths that would be cheaper, faster, and environmentally less

disruptive. The most popular alternative was called a "wick drain" and consisted

of a prefabricated plastic band that had a geosynthetic filter fabric wrapped

around a central plastic core that the water moved through after it was filtered

through the wrapping (figure 36). Although these wick drains had many

significant advantages over sand drains, there were many unanswered questions

regarding design assumptions, laboratory screening tests, quality control,

installation methods, durability, and generic acceptance specifications.

Recognizing the huge potential of prefabricated vertical drains, industry

responded with the development of a large number of different and mostly

proprietary models; some good, others not so good. Engineers soon discovered the

need for generic testing protocols to help them select and approve satisfactory

drains.

A comprehensive FHWA research study was initiated to develop

generic testing procedures and sample specifications, as well as complete

descriptions and helpful guidance for design and construction. The study also

included a parallel investigation of prefabricated drainage sheets and boards

that were becoming popular for use behind retaining walls.

For more

detailed descriptions of types and physical characteristics of these drainage

materials, the best source is FHWA-RD-86-169 for wick drains, and FHWA-RD-86-171

for sheet drains (46,47). These reports also provide a discussion of design

considerations, recommended design procedures, guideline specifications, and

advice on construction installation, control, and performance evaluation.

3.7 Publications and Implementation Items

Research and development activities for ground improvement techniques were very successful. Numerous quality reports and manuals were generated from this project, which is by far the most comprehensive research investigation of this topic by any single organization in the world. Numerous technology transfer items were disseminated to accelerate the implementation of this new information to highway practitioners. Many changes were made to the AASHTO Specifications (see chapter 7) and several FHWA training courses and technical circulars were developed on the basis of the research results.