6.0 Inspection Efficiency Evaluation

This section addresses Goal Area 2: "Determine how the ISSES makes the inspection process more efficient and effective, in turn contributing to improved highway safety."

Section 6.1 presents the research objectives and hypotheses that guided this portion of the evaluation along with a high-level description of the analysis. Section 6.2 provides an overview of Kentucky's current approach to selecting vehicles for inspection. Section 6.3 provides detailed information on the techniques used in data collection as well as how these data were used to meet the objectives of the independent evaluation. Understanding the demographics of the motor carrier population and the relative risk associated with truck traffic at the Laurel County station (objective 1.2) is covered in Section 6.4. Objective 2.2 is addressed in Section 6.5, where the inspection efficiency of the Laurel County station is assessed. Section 6.6 covers the safety benefits calculated based on various scenarios if KVE inspectors had instant, real-time (or advance) access to truck and motor carrier historic safety/inspection/driver information via ISSES or other CVISN technologies. Section 6.7 examines the potential effect of other credentialing data sources on safety benefits. Sections 6.6 and 6.7 together address objective 2.3, on the integration of ISSES data with external data sources.

6.1 Objectives and Overall Approach

This chapter will cover the following objectives and hypotheses:

Objective 1.2 Use data from the field test to determine the distributions of kinds of vehicles traversing the weigh station under normal conditions. This provides a baseline for reference in assessing the highway safety benefits of the ISSES.

Hypothesis: The distribution of commercial vehicles passing the London site, relative to the respective motor carriers' SafeStat score ranges, is similar to that of the national population of commercial vehicles.

Objective 2.2 Measure the ability of the ISSES to improve inspection selection efficiency, and in turn to yield reductions in crashes and breaches of highway security.

Hypothesis: The ISSES can help inspectors focus their efforts on higher-risk trucks.

Objective 2.3 Explore options for integrating the data available from the ISSES with existing safety, enforcement, and administrative data sources, and prepare models or plausible scenarios for Kentucky or other states to apply.

Hypothesis: Data from ISSES can yield important information for commercial vehicle enforcement and administration when combined with data from other state and federal sources.

Data to address these objectives and hypotheses were collected through various methods: (1) interviews and site visits with various KTC and KVE personnel; (2) a 2-week field study at the Laurel County inspection site; (3) various federal and state safety data sources; and (4) past federal studies that relate to CMV crashes and safety. Listed below are the main data sources used and the role that each data source played in achieving the goals of the evaluation.

- Interviews with KVE inspectors and KTC specialists. Information was compiled to characterize and understand Kentucky's current approach to the roadside screening and inspection process, the data sources used in the process, and how the ISSES fits into the overall inspection selection approach.

- USDOT numbers for all trucks going through the ISSES portal at the Laurel County station during a 2 week field study (during normal daytime hours). This collection of USDOT numbers provided a representative sample of carriers that pass through the ISSES at the Laurel County station. The USDOT numbers were used to acquire various kinds of carrier demographic information as well as current and historical safety information from federal and state data sources.

- NORPASS (electronic screening/preclearance) bypass decisions per truck for one week during field study. This data was used to determine the number of trucks that utilize the NORPASS system, with screening decision criteria as set by Kentucky, at the Laurel County station as well as provide an idea of the percentage of trucks that are given green and red lights to either bypass or pull into the station. Information on these trucks, when combined with data from the trucks that went through the ISSES, provided a fuller profile of truck traffic that went by the inspection station during the second week of the field study.

- Electronic copies of inspections performed during 2-week field study. These inspections provided the evaluation team with insight into the types of vehicles that are selected for inspection at the Laurel County station. The inspection report contained information on the specific types of violations found during the inspection. In addition, USDOT numbers of vehicles inspected were cross-referenced with federal and state data sources to learn more about the safety risk of carriers that are inspected at the Laurel County site.

- Electronic copies of Kentucky statewide inspections spanning over 2.5 years. These inspection reports provided a more robust picture of trucks selected for inspection statewide. From these inspections, state OOS rates were calculated for various groups of trucks as defined by their safety risk. The inspections also identified those OOS violations that occur most frequently in the population and allowed the evaluation team to calculate the probability of occurrence for these most commonly occurring OOS violations.

- SAFER. A copy of the Safety and Fitness Electronic Record (SAFER) carrier and inspection tables was obtained from the Volpe Center at the time of the field study. SAFER was used to obtain current safety risk measures such as SafeStat (Motor carrier'safety Status Measurement System) and Inspection Selection System (ISS) scores. These sources were in addition to other historical safety-related information on trucks observed during the field study as well as those trucks that were inspected statewide over the past 2.5 years. SAFER enabled the evaluation team to place both observed and inspected trucks into safety risk categories defined by their current ISS score.

- Kentucky Clearinghouse. A copy of the Kentucky Clearinghouse database was obtained at the time of the field study. This database showed vehicle and driver OOS rate information on carriers that traversed the station. Also, registration and insurance status about each carrier was extracted so that it could be combined with other safety-related information to form a clearer picture of each motor carrier.

- Infrared Images. It was planned to obtain IR (thermal) images on a sample of trucks that passed through the ISSES at the Laurel County station during the field study. Unfortunately, only images from a two-day training session at the Kenton site, and none from Laurel, were made available to the evaluation team. Miscommunication between the evaluator and the vendor resulted in the Laurel County thermal imaging data being inadvertently discarded. However, results from a prior research study conducted in 2000 for FMCSA to evaluate a similar IR imaging and video package, known as IRISystem, were used to estimate the increase in OOS orders issued when trucks are screened via IR imaging.2

- Large Truck Crash Causation Study (LTCCS). Data from the LTCCS were used to identify those OOS violations that present a high relative crash risk. This was important in that a larger number of crashes could be avoided by finding those OOS violations in an inspection that have a higher relative crash risk.

- 2003 National Truck Fleet Safety Survey. An FMCSA-sponsored survey in which approximately 2,800 trucks were selected at random for inspection in order to estimate the percentages of trucks and drivers that operate with OOS conditions. These OOS rates were used as estimates for the probability of finding an OOS violation when inspectors select trucks for inspection randomly.

- Large Truck Crash Facts – 2005. Federal statistics on the number of crashes, injuries, and fatalities in which large CMVs were involved were used to help estimate the safety benefits accruing from various roadside deployment scenarios.

The goal of roadside enforcement is to avoid as many crashes as possible by putting unsafe vehicles OOS before the OOS conditions present on the vehicle contribute to a crash. A means to this end is to improve the inspection selection process in such a way that the greatest benefit can result from a fixed number of inspections. This makes the most efficient use of limited time, human resources, and facilities. The overall approach of this evaluation was to first assess the effectiveness of the current inspection selection methods at selecting high-risk trucks.

In addition, alternative methods for selecting vehicles for inspection were evaluated based on potential availability of information from the above data sources. Several forms of available evidence and inspection selection methods were combined in various ways to develop hypothetical scenarios for the safety analysis:

- Selecting vehicles randomly for inspection, to provide a starting point from which to assess the contribution of the inspectors' knowledge and experience.

- The current vehicle selection process used in Kentucky, which relies primarily on inspector judgment.

- Using electronic screening3 to eliminate all low- and medium-risk carriers from selection consideration, so that inspectors can focus on high-risk trucks or those with insufficient safety information in federal databases. This approach uses the carrier's ISS score, a rating system promoted by USDOT.

- Using the carrier's vehicle and driver OOS rates, which are the metrics preferred by Kentucky in roadside enforcement.

- Using information on OOS violations with a high relative crash risk

- Using thermal/IR brake images from the ISSES.

Finally, the evaluation measured the success of these new inspection selection methods by simulating what would happen if inspectors used these kinds of information to select high-risk trucks for inspection. The measures used to estimate success were the estimated number of crashes, injuries, and fatalities avoided.

6.2 Kentucky's Approach to Inspection Selection

One of the main objectives of the Inspection Efficiency analysis was to measure the ability of the ISSES to improve inspection selection efficiency. One hypothesis tested was that the ISSES could help inspectors focus their efforts on higher-risk trucks. In order to best address this hypothesis, it was crucial first to understand the current inspection selection philosophies and methods used at the Laurel County site as well as in Kentucky overall. This was accomplished through interviews with KVE inspectors and other personnel from the Laurel, Simpson, and Kenton County stations where the ISSES has been deployed.

Information from these interviews was compiled to characterize Kentucky's approach to the roadside screening and inspection process. Specifically, the ways that Kentucky inspectors utilize aspects of the ISSES or other CVISN screening and safety information exchange technologies to help them make inspection selection decisions were documented. The range of manual and automated inspection selection methods and supporting data systems (e.g., Query Central) that are currently being used were identified as were any state-of-the-art practices. Specific attention was focused on the degree to which sites are currently integrating various national and state data sources.

6.2.1 Summary of Approach

Kentucky has developed an algorithm for observing and pulling in trucks for inspection. The algorithm is used at inspection stations where an office support assistant is available to capture (by keypad data entry) the USDOT or the Kentucky Use (KYU) numbers and, if possible, the unit number from every truck that enters the station. The algorithm relies heavily on this truck identifying information as well as the Kentucky Clearinghouse, a state database containing carrier-based safety, credentialing, and licensing information that is housed at the Kentucky Transportation Cabinet in Frankfort. As Kentucky does not have sufficient resources to place such an office support assistant at each inspection station, the algorithm is not used at every Kentucky inspection station. This section presents the methodology used to select vehicles for inspection at sites where an office support assistant is available to capture truck identifying information. This is followed by a discussion of inspection selection practices at other sites, including the Laurel County northbound station, where the algorithm is not used, because no office support assistant is assigned to this station.

Table 6-1 describes the data contained in the Kentucky Clearinghouse and how it is used for inspection selection purposes. Most information in the Clearinghouse comes from internal Kentucky data sources supplemented with information obtained through federal safety systems such as SAFER or SafetyNet. Some data values in the Clearinghouse are updated in real time while others are updated hourly or daily from their respective sources.

| Field | Description |

|---|---|

USDOT Number |

The USDOT field is populated from a daily update from SafetyNet. |

Census National File Indicator |

Indicates whether the USDOT number was pulled from the Motor Carrier Management Information System (MCMIS) Census File meaning the carrier is on file with the USDOT (Y) or if the record was created by Division of Motor Carriers personnel as they were issuing various credentials during that day (N). The Y should replace the N as soon as SafetyNet refreshes with the issuance of the new USDOT number, which should be within a few days. |

USDOT Status |

The carrier's status with USDOT as seen in SafetyNet. |

Driver OOS Rate |

The driver OOS rate as posted for the company in SafetyNet. |

Vehicle OOS Rate |

The vehicle OOS rate as posted for the company in SafetyNet. |

OOS Rate |

The larger of the Vehicle OOS or three times the Driver OOS Rate is posted in this field, and is subsequently used in all screening calculations. (Because most of Kentucky's screening is focused on carriers whose OOS rates are above the national average, the driver OOS number is multiplied by three so as to better be able to compare the two numbers – this concept is explained further in the discussion following this table). |

Number of Observations at Kentucky Facilities |

A four digit number representing the number of times any of the company's vehicles had been recorded (data entered) by a state official as they were observed passing through one of Kentucky's scale facilities. This number currently can be between 0 and 500, and resets to zero after the system flags and notifies the scale personnel that an inspection may be warranted. |

KY Intrastate Tax License Status and Reason |

The status of the carrier's KY Intrastate Tax license as it is currently displaying in the Automated Licensing and Taxation System (ALTS). The status for this field is updated in real time. |

KY Intrastate Tax Inactive Reason |

If a carrier is inactive, this field will display the reason the carrier has been made inactive [(C) for cancelled in good standing, (R) for revoked, or (S) for suspended, which means that the license has only been inactive for less than 30 days]. |

IFTA Status |

The status of the carrier's real-time International Fuel Tax Agreement (IFTA) [(A) for active, (I) for inactive and (N) for no data available] of KY IFTA carriers from the ALTS mainframe system, as well as the IFTA status of any carrier whose base jurisdiction utilizes the IFTA Clearinghouse to forward the status of their carriers. The inactive status for a non-KY carrier can only be posted if the jurisdiction identifies the revoked carrier within the Clearinghouse by their USDOT number. |

IFTA Reason |

If a carrier is inactive, this field will display the reason the carrier has been made inactive [(C) for cancelled in good standing, (R) for revoked, or (S) for suspended, which means that the license has only been inactive for less than 30 days]. |

IFTA State |

Indicates the IFTA base jurisdiction |

SSRS Status |

The field flags for-hire motor carriers that have expired liability insurance. This data begins with a daily file extract from SAFER, which goes to the Single State Registration System in Illinois. From there, an extract is passed back to Kentucky, where it populates this field and displays all interstate, for-hire motor carriers' status: (A) for active and (I) for inactive. Private and intrastate carriers are populated with an (N). While the SSRS has been repealed (to be replaced by the UCR program), the data that is obtained for this field is and will continue to be an accurate indicator for insurance and operating authority status. |

IRP Status |

The status for the carrier's International Registration Plan (IRP) is updated each hour from the Cabinet's Oracle IRP system. Any change in status is warehoused within the IRP system until the top of the hour, when a file is created to move the data from the IRP System to the KY Clearinghouse. |

IRP Expiration Date |

Any change in the IRP expiration date is passed hourly to the Clearinghouse. The date is the expiration date of the IRP plates issued to this company by Kentucky. When new plates are issued, the expiration date is advanced a year and the system is updated within an hour. If the plates are not renewed in the IRP system by the expiration date, the KY Clearinghouse will change the (A) in the status to an (I) to indicate the plates are expired. Within an hour the update will take place in the Clearinghouse, but can be updated on line immediately. |

Extended Weight Coal Decal |

The current status of the Extended Weight Coal Decal, which works in an identical fashion as the IRP system. It is also populated from an Oracle based EWD system and the status will set to (I) if the decal is not renewed. |

NORPASS enrollment status |

Denotes if the carrier is enrolled with Kentucky's NORPASS screening system. This flag (Y/N) is set whenever a company registers its vehicles with NORPASS and the information is loaded into ky's transponder system. The information is refreshed each hour in the same process that provides the transponder system with its master flag setting and the random pull-in percentages. |

ICC Exempt Authority |

Denotes whether the company has additional ICC exempt operating authority. This information is updated in real time from ky's mainframe systems that handle these authorities. |

Kentucky for-hire Authority |

Denotes whether the company has additional KY for-hire operating authority. This information is updated in real time from ky's mainframe systems that handle these authorities. |

PRISM Status |

Comes from the MCSIP field within SafetyNet. This flag is updated daily with the refresh from SafetyNet. If SafetyNet indicates this company is in MCSIP, the field will display a (Y), otherwise an (N) will display. |

KYU Exempt |

Used to override the observation systems requirement for a large truck to have an active KYU number on file. For example, an 80,000 pound farm plated truck would get stopped each time it went through a scale because it did not have a KYU number. A tractor trailer combination licensed for only 55,000 pounds would get pulled in each time as well. By placing a letter in this field [(F) for farm, or (W) for weight] the system will ignore the KYU edit check. |

KYU Number |

Kentucky Use Number |

KYU Status |

Denotes the status of the KYU number [(A) for active, (I) for inactive] |

KYU Reason |

Will display the reason the carrier has been made inactive [(C) for cancelled in good standing, (R) for revoked, or (S) for suspended, which means that the license has only been inactive for less than 30 days]. |

Exam |

A multi-purpose field that could be used to stop vehicles of companies who were active for all criteria in the system, but needed to be stopped for some other reason. (1) means that there were no vehicles listed on KYU vehicle inventory system. (2) is generally used to stop a carrier and obtain a valid address from them. (3) indicates that the scale personnel should contact the radio room for additional instructions on this carrier. (4) is used to override an inactive KYU number (in most cases this was due to a delinquent tax return being present in the state office, but for some reason could not be processed at that time). (5) is used to stop carriers who had not provided a valid USDOT number to cross reference their KYU number. |

OOS Grace Date |

Used to override the OOS rate data that is feeding into the Clearinghouse. Example: The OOS rate could be altered and a grace date can be populated to establish the length of time the system will recognize the altered information. For example, if a company had been inspected a number of times recently due to a poor OOS rate and had drastically improved their equipment, the OOS could be manually lowered and a grace date could be set for three months out to allow the inspections to make it through the system and update the company's rating. The Clearinghouse would ignore the daily data that was coming from SafetyNet until the grace date passed and then would proceed as usual from that day forward. The process would work the same for SSRS and PRISM. |

SSRS Grace Date |

Used to override the SSRS status data that is feeding into the Clearinghouse. |

PRISM Grace Date |

Used to override the PRISM status data that is feeding into the Clearinghouse. |

6.2.2 Algorithm for KY Clearinghouse Observation Inspection Pull-Ins

This section describes the algorithm that determines whether a vehicle is targeted by the system to be pulled in for inspection or not, using data from the Kentucky Clearinghouse. Most of the computation is focused on the OOS fields in the Clearinghouse. Random pull-ins for transponder-equipped vehicles on the mainline are also initiated using this algorithm. Although it does not have an official name, the algorithm will be referred to in this report as the Kentucky OOS Rate Inspection Selection Algorithm.

Some Kentucky inspection stations utilize office support assistants to key in the USDOT or KYU numbers from the cabs of vehicles as they slowly pass the scale house during hours when inspectors are on duty. The truck identification information is typed into a computer terminal connected directly to the Kentucky Clearinghouse. Then, information on the carrier is compiled and sent back instantaneously to personnel at the inspection station. An inactive status in such fields related to USDOT number, KYU number, IFTA, IRP, SSRS, Kentucky Intrastate Tax License, and others, causes the system to display the specific problem on the office support assistant's screen and invoke the printer to provide a paper copy listing the issue as well. The office support assistant then makes a decision whether to turn on the "PARK" signal on the variable message sign for the vehicle to pull into the lot to park the vehicle and enter the scale house. The driver would then enter the scale house and work with KVE personnel to resolve the issue.

The decision to have the vehicle pull into the lot is based on the office support assistant's quick evaluation of the information available from the Clearinghouse before the truck has passed under the directional signage. There are instances where the Clearinghouse identifies issues with the carrier but the office support assistant decides to let the vehicle continue back to the mainline. For example, the office support assistant may see that the screen is displaying a name other than the name displayed on the vehicle that was just keyed, leading him or her to believe that the DOT number may have been typed incorrectly. The office support assistant may also make a judgment call that there is not enough personnel available to handle additional vehicles at this time. In addition, the speed of the vehicle or the time involved in the evaluation may be such that the vehicle is past the variable message sign before the office support assistant can act.

Inspection decisions using the Clearinghouse are based on three factors: 1) OOS rates; 2) the carrier's status in the Performance and Registration Information Systems Management (PRISM) Target File; and 3) the number of times the carrier's vehicles have visited a Kentucky station since their last inspection. The carrier's vehicle and driver OOS rates are both pulled down daily from SafetyNet and loaded into the Clearinghouse. In addition, the PRISM Target File [in the form of the Motor carrier'safety Improvement Program (MCSIP) A, B, & C carriers] is pulled from SafetyNet and loaded as well. A counter system was developed within the Clearinghouse to keep track of how often a carrier's trucks enter Kentucky inspection stations. Using a series of adjustable pull-in rates maintained in the Clearinghouse, the system determines which vehicles should be "kicked out" and displayed on the screen indicating that the office support assistant should consider selecting that vehicle for inspection.

The following is a quick explanation of the counters in the Clearinghouse. There are currently 16 scale facilities in Kentucky, all of which are equipped with a data entry system for screening trucks. When staffed with an office support assistant, each of these facilities utilizes the single Clearinghouse database located in Frankfort. Each time the weigh station personnel enter an observation (keying a USDOT number and unit number) into the database, the master record for that company has a counter that is increased by one. For example, if the counter is set at 278 for a particular carrier, and an observation for that carrier is recorded at Morehead Scales, the counter increases to 279. If three seconds later an observation is recorded at Fulton Scales for a different vehicle operated by the same carrier, then the carrier's counter value increases to 280. This counter increases regardless of whether the observation shows an active or inactive status for the carrier.

The purpose of the counter is to establish how many times the company's vehicles have been "observed" or entered into the system since the last time the system kicked one out to be inspected. As soon as the system designates a company's vehicle for inspection, the counter rolls back to zero and the next observation is recorded as "1." The system knows when to select a vehicle for inspection by using the adjustable pull-in rates shown in Table 6-2. These pull-in rates apply both to sites where an office support assistant is assigned to the scale house and to sites equipped with the NORPASS electronic screening system. The Clearinghouse utilizes both the vehicle and driver OOS rate to determine when a company should have their next vehicle pulled in for inspection. Since the national average for driver OOS is roughly a third of the vehicle OOS, the driver OOS Rate is multiplied by 3 to even the two numbers out so that the higher of the two numbers can be used for screening. (The driver OOS multiplier can be altered in the algorithm to accommodate different inspection selection strategies.) Throughout the remainder of this section, OOS rate refers to the maximum of the vehicle OOS rate and three times the driver OOS rate.

| Carrier OOS Rate* | Carrier Pull-In Rate (Truck selected for inspection by Clearinghouse algorithm) | NORPASS Pull-in Rate as Defined by Kentucky |

|---|---|---|

100% |

Every 20th Truck |

50% |

76-99% |

Every 5th Truck |

40% |

50-75% |

Every 10th Truck |

20% |

25-49% |

Every 100th Truck |

10% |

0 - 24% |

Every 500th Truck |

5% |

Depending on where that OOS rate falls within the ranges provided in the first column of Table 6-2, the carrier pull-in rate in the second column sets the point at which the counter for each particular company initiates a "kick-out," i.e., notifies the weigh station personnel to inspect a vehicle, and automatically reset the counter to zero. For instance, a carrier with an OOS rate of 58 percent has one out of every 10 of its trucks kicked out for inspection, while a carrier with a more favorable safety rating (e.g., one with an OOS rate of 5 percent) sees every 500th truck kicked out. By design, carriers with a 100 percent OOS rate are pulled in less frequently than carriers with OOS rates between 50 and 99 percent. Kentucky has found that a large number of carriers with a 100 percent OOS rate as displayed in the Clearinghouse are actually companies that have had only one inspection, which happened to result in an OOS order. Since there are a significant number of such carriers and to better manage the number of kick-outs at the station, a decision was made to look at these carriers with less frequency than carriers with slightly lower OOS rates.

When a truck is kicked out for inspection, the office support assistant's screen and printer immediately displays information such as the following example:

DOT NO: 1787878

KYU NO: 007878

COMPANY NAME: TO-MARK-IT TRUCKING

INSPECT 066

This would indicate to the office support assistant that the vehicle that he or she just entered had a vehicle OOS of 66 percent or a driver OOS of 22 percent, either of which would be significantly greater than the national average. Because the carrier OOS rate fell between 50 and 75 percent, it would also mean that the vehicle in question was the tenth vehicle to be observed (or entered into the Clearinghouse system) since the last time the system had kicked a vehicle out from that company to be inspected.

In addition to the company counter that every carrier has, the Clearinghouse also maintains an internal counter for every carrier in the PRISM Target File. If the carrier is in the PRISM Target File, a separate and independent counter is created to keep track of vehicle observations for PRISM purposes. When that company's PRISM counter hits 5, the counter reverts to 0 and the office support assistant's screen and printer displays the following:DOT NO: 1787878

KYU NO: 007878

COMPANY NAME: TO-MARK-IT TRUCKING

PRISM Y

The carrier observation counter and the PRISM counter are completely independent of each other, and as soon as a carrier is taken off the PRISM Target File, its PRISM counter is disengaged. The observation counter is constantly in use and increases regardless of the circumstances of the observation.

All of the data fields described above can be altered to focus inspection kick-outs as KVE sees fit. Currently, KVE uses five levels of pull-in rates, but the system can handle up to 10 levels. Also the settings are such that every 500th vehicle of a company that is at or below the national average for OOS is kicked out for inspection. That can be changed at any time to any arbitrary number if so desired. The driver OOS multiplier is currently set to 3 so that any company with a driver OOS rate above 8 is screened at a much higher level, but that could be increased, for example, to 8 or 9, so that KVE could focus on companies with high driver OOS rates.

At the current levels set by the table, there are more kick-outs than scale personnel can handle. This is done mainly for two reasons. First, it provides the scale personnel with plenty of discretion as to which vehicles they inspect. In addition to the inspection decision produced by the inspection selection algorithm, an inspector may visually spot a problem with a vehicle (flat tire, unsecured load, etc.), or choose to inspect a PRISM-identified carrier, or an overweight vehicle. These obviously needed inspections require the scale personnel to ignore the kick-outs due to lack of time and resources. Secondly, each inspection site has different levels of personnel, and the staff there are to complete their assigned number of inspections. It would be virtually impossible to program the system to kick out the right number of vehicles for the day and have them spaced out appropriately for the inspectors to handle. This would also require drastically decreasing the pull-in rates so that possibly only six or eight kick-outs occur per inspector on any given shift. Potentially, three or four could occur within an hour, and then nothing else might show up for another three or four hours.

As Table 6-2 indicates, the Kentucky Clearinghouse utilizes a built-in pull-in rate that is passed to the NORPASS System for random red light pull-ins from the mainline. As it is with the inspections, the higher a carrier's OOS rate, the fewer green light bypasses allowed. Currently a carrier at or below the national average for OOS would be required to pull into the station 5 percent of the times that its trucks encounter a NORPASS-equipped Kentucky inspection station. Alternatively, carriers with OOS rates between 76 and 99 percent would be required to pull into the station at a rate of 40 percent. These rates can also be altered as needed by KVE. PRISM carriers (i.e., carriers in MCSIP) get red lights 100 percent of the time, when the weigh station is open.

6.2.3 Inspection Selection Methods at Laurel County Inspection Station

At the time of the field observation, there was no regular office support assistant assigned to manually enter USDOT or KYU numbers of trucks passing the scale house at the northbound Laurel County inspection site. Thus, the inspection selection algorithm associated with the Kentucky Clearinghouse was not used at the Laurel County station. Rather, trucks were predominantly selected for inspection based on the inspector's visual observation of the trucks as they entered the station, the inspector's personal knowledge of the carrier and its corresponding safety history, and the inspector's professional judgment and experience. This is important to keep in mind as analyses on inspection efficiency and safety benefits are presented in Sections 6.5 and 6.6, respectively.

6.2.4 Traffic Flow at Laurel County Inspection Station

The Laurel County ISSES site (see Figure 3-1 above) is equipped with transponder-based mainline electronic screening via NORPASS and has a high-speed, mainline weigh-in-motion (WIM) scale linked with the NORPASS system. There is also a low-speed WIM on the sorter lane leading from the mainline to the scale house. All trucks are required to enter the station when it is open, with the exception of those NORPASS participants that are given permission to bypass. The layout for the site is such that there is one exit ramp from the highway that leads to a sorter-lane WIM. Trucks on the ramp with an acceptable WIM reading are directed to a lane on the west (highway) side of the scale house, which is the lane that contains the ISSES equipment. Overwidth trucks are directed to a static scale on the east side of the scale house, because the width of the ISSES portal cannot accommodate overwidth vehicles. Also, any vehicles that lack a valid low-speed WIM weight reading or are suspected of being overweight are directed to the static scale.

For trucks that pass through the ISSES equipment, information from the bulk radiation detection monitor, thermal imaging inspection system, vehicle classification system, USDOT number reader, and license plate recognition system are communicated to officers in the scale house. At the time of the field observation, these systems were not integrated with any legacy Kentucky or federal safety data source. As such, ISSES information was generally not used in the inspection selection decision.

Once trucks have been weighed on the sorter-lane WIM and/or the static scale, inspectors make a decision whether to let the truck continue to go straight back to the mainline if there are no problems or to have the truck pull around to the back of the station into the inspection area or shed for further examination by motor carrier enforcement personnel. This decision is communicated to the driver via lighted arrow signs located on both sides of the scale house.

6.3 Field Observational Study Data Collection

The Kentucky field data collection was conducted from June 11 to June 22, 2007 at the Laurel County northbound weigh station. Prior to the actual field data collection, introductory visits to the site were made by evaluation personnel in July and August, 2005, shortly after the system had been deployed. A preliminary site visit was also made on January 24, 2007, to both the Laurel County northbound I-75 and the Kenton County southbound I-75 ISSES sites. Personnel from the KTC and the system vendor (TransTech/IIS) were the principal contacts. The main goal of this January visit was to observe the operations at the stations and consult with members of the deployment team and inspectors. Of particular interest to the Inspection Efficiency portion of the evaluation was to understand the truck movements through the stations, the information available to inspectors to make decisions on which trucks to inspect, and how inspectors use this information to make inspection decisions. A second goal of the preliminary site visit was to determine how data could be extracted from the ISSES and other IT systems on-site and how best to locate researchers within the scale house at Laurel County to capture vehicle identification information visually. Researchers met with inspectors and officers from KVE as well as information technology personnel to understand the screening and inspection operations and took tours of both inspection stations.

Beginning on June 11, 2007, a researcher from the evaluation team was assigned to the scale house to observe the vehicles entering the weigh station during normal daylight hours while inspectors were present. To the extent possible, each entering vehicle was identified by USDOT number. Periodic time values were also recorded for reference and data matching purposes. This information was recorded via the researcher speaking into a digital voice recorder. The digital voice recorder was the preferred medium for data capture, because it allowed the researcher to capture the USDOT number without having to look away from the vehicle. The audio data were then transcribed to a Microsoft Access database application and quality-checked. Trucks passing by the scale house during daylight hours were no more than 10 feet from the window and, for the most part, were going at a very low speed through the ISSES, thus enabling the research team to capture vehicle identification information for most of the vehicles. Based on feedback from the data collector, it is estimated that no more than 5 percent of the vehicles going through the ISSES were missed. Mainly, truck information was missed when many trucks were too closely spaced and traveling too fast as they passed the scale house window for the data collector to capture all information. It is assumed that the safety ratings and other characteristics for the missed trucks are no different than those for the complete population of trucks traveling on this section of I-75 in Kentucky.

Table 6-3 shows the dates and times that a researcher was on duty during the field study. For the most part, a researcher was collecting USDOT information from passing trucks during normal business hours while at least one inspector was at the station inspecting vehicles. One exception was on Tuesday, June 12, where no data collection occurred due to an unplanned absence. Also, the station was closed after 11 AM on Tuesday, July 19 for a meeting of KVE officials, so data collection on that day was limited to the morning.

| Date | Time | Comment |

|---|---|---|

Monday, June 11 |

8:00 AM – 4:00 PM |

|

Tuesday, June 12 |

Not applicable |

No USDOT number data were collected; researcher unavailable |

Wednesday-Friday, June 13-15 |

8:00 AM – 4:00 PM |

|

Monday, June 18 |

8:00 AM – 4:00 PM |

|

Tuesday, June 19 |

8:00 AM – 11:00 AM |

Station closed at 11:00 AM for staff meeting. It was not reopened until 6:00 PM |

Wednesday-Thursday, June 20-21 |

8:00 AM – 5:00 PM |

|

Friday, June 22 |

8:00 AM – 4:00 PM |

It was desirable to characterize all vehicles that traversed the Laurel County station during the time of the field study so that the sample of trucks that can be identified could be considered a representative sample of all trucks that travel this section of the highway. However, in certain cases, vehicles can bypass the station, making it impractical to identify these vehicles visually because of their mainline speeds and the distance from the scale house. Vehicles can legally bypass the station because: 1) they were cleared as a result of NORPASS; or 2) the station was closed temporarily to prevent queuing on the mainline as they approached. Vehicles can also bypass the station illegally by not stopping when the station is open or, in the case of e-screening participants, not entering the station when a red light signal is communicated to the driver. The NORPASS ModelMACS screening equipment provides an audible alarm in the scale house if any transponder-equipped vehicle bypasses the station without receiving a green light.

The Kentucky Transportation Cabinet provided a file of all NORPASS-participating trucks that traversed the highway where the Laurel County inspection station was located for the second week of the two-week study. Information provided in the file for the second week of the field study included:

- Time and date when the vehicle's transponder was read

- Decision made on truck (bypass or pull in)

- Reason for decision

- Carrier name

- USDOT number

- Vehicle unit number

- State of Registration (IRP state)

- Vehicle license plate number.

The trucks that were given a bypass signal during the hours of data collection at the site were added to the list of trucks that were captured by the on-site data collector to get a more complete list of truck traffic that went by the inspection station during the second week of the field study. E-screening participating trucks that were pulled in and went through the ISSES portal would already have been captured by the data collector. KVE personnel estimated that approximately 8 percent of the trucks that enter the Laurel County weigh station cross the static scale, instead of going through the ISSES portal. These "static scale" trucks, most likely overwidth or flagged as potentially overweight on the low-speed ramp WIM, are not accounted for in this analysis.

An assumption was made that the population of vehicles that bypass the station when it was temporarily closed is not significantly different from the population of trucks that came in when the station was open. Therefore, no identifying information was captured on vehicles that bypassed when the station was closed. The major closure was on Tuesday, June 19. Based on hourly truck counts observed on that day, it is estimated that approximately 1,000 trucks bypassed the weigh station during the late morning/afternoon station closure. There were instances where the station was closed for very short periods of time due to excessive backups on the ramp leading from the mainline to the weigh station. The number of trucks that bypassed the station during these brief closures was minimal. Also, it is unknown what proportion of vehicles bypass the station illegally, although it is assumed to be a low percentage of the truck traffic for purposes of this study.

Electronic copies of reports from all inspections conducted at the Laurel County station during the two-week field study were obtained from KVE at the conclusion of the study. This provided evaluators with a list of specific vehicles that were chosen for inspection from the truck traffic that traversed the station during the field study. These inspection reports detailed the level of inspection, results of the inspection, and any violations or OOS orders. KVE also provided a database of all inspections performed at all fixed and mobile sites in Kentucky for the 32.5-month period from January 2005 through mid-September 2007. Information from these inspection reports provided analysts with accurate information as to OOS rates for Kentucky inspections for different classes of vehicles.

The Kentucky Department of Motor Vehicles also provided a copy of the Kentucky Clearinghouse Database. The data in the Clearinghouse changes daily, so it not possible to know the exact contents of the Clearinghouse for each day of the field study. Rather, an attempt was made to get a copy of the database as close to the time of the field study as possible. Due to a delay in making the file available to researchers, a snapshot of the database was obtained by researchers in August 2007, reflective of information as of July 17, 2007, roughly one month after the field study. It is unknown to what degree the contents of the Clearinghouse changed between the end of the field study and July 17. However, for purposes of this study it is assumed that any changes to a carrier's profile would be minimal. Registration and insurance status about each carrier was extracted so that it could be combined with other safety-related information to form a more complete picture of each motor carrier. More information on the Kentucky Clearinghouse and the specific fields in the database is presented in Section 6.2.

Unfortunately, video images from the IR/thermal imaging camera during the field study at the Laurel site were not available to the evaluation team. However, video data from the thermal imaging system were provided to the independent evaluator on vehicles that passed through the Kenton County inspection station during a two-day training session on July 31 and August 1, 2007. Although these video images were not useful to the Inspection Efficiency portion of the evaluation, because they did not correspond to the truck traffic observed during the two-week field study, they were reviewed in connection with the system performance study, covered in Section 5.0.

6.4 Characteristics of Truck Traffic at Laurel County Station

A quantitative, statistically rigorous baseline picture of the commercial traffic using I-75 northbound through southern Kentucky is important in preparing strategies for helping vehicle inspectors to focus on higher-risk carriers and vehicles. First, summary demographic information on truck traffic that traversed the Laurel County inspection station during the field study was collected. A second key factor in this effort was describing and understanding the relative safety risk of these trucks. Information on the trucks observed entering the site or legally bypassing the site via NORPASS during the field study were used.

The purpose of this section is to describe the truck traffic near the Laurel County inspection station and to compare characteristics of this population to the national population of motor carriers. Table 6-4 provides an overview of the numbers of trucks that were observed.

| June 11 – June 15 | June 18 – June 22 | Complete Field Study | ||||

|---|---|---|---|---|---|---|

| Number of Trucks | Percent | Number of Trucks | Percent | Number of Trucks | Percent | |

Entered Station and Captured by Data Collector |

5,588 |

100.0 |

6,738 |

93.1 |

12,326 |

96.1 |

Bypassed Station via NORPASS |

NA* |

NA |

498 |

6.9 |

498 |

3.9 |

Total |

5,588 |

100.0 |

7,236 |

100.0 |

12,824 |

100.0 |

Overall, USDOT numbers were captured for 12,326 CMVs entering the Laurel County station during the two-week field study. Information on an additional 498 vehicles that legally bypassed the station during the second week of the study was captured via NORPASS. Because of a software or hardware archiving failure associated with the ModelMACS screening system in Kentucky, bypass information for the first week of the study could not be used because key pieces of information were missing from the NORPASS file that reports truck bypass and pull-in information. The 498 trucks that bypassed in the second week were added to the 12,326 captured by the on-site researcher for a total of 12,824 vehicles used in the analysis. A total of 57 trucks were inspected during the first week of the field test, while 36 trucks were inspected the second week.

Table 6-4 describes only those trucks that were observed either by the data collector or NORPASS. As noted previously, identifying information was not captured on a small subset of vehicles. For example, trucks that did not pass through the ISSES but were instead directed automatically or manually to the static scale were not captured by the data collector. Due to the rate at which trucks passed by the scale house window after going through the ISSES and the distance between the ISSES equipment and the static scale on the opposite side of the building, it was not possible for the data collector to capture USDOT numbers from both sets of vehicles. In consultation with KVE, the KTC estimates that, when the station is open, approximately 8 percent of the daily truck volume passes over the static scale as opposed to going through the ISSES. In addition, it is estimated that the researcher was unable to obtain identifying information on about 5 percent of the vehicles traveling through the ISSES, mostly because consecutive trucks were at times traveling too fast past the scale house window to capture all information. While such unidentified trucks are excluded from this analysis, it is assumed that the safety ratings and other characteristics for the small set of missed trucks are identical to those trucks from which identifying information was captured.

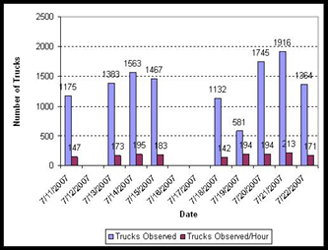

Figure 6-1 summarizes the number of trucks observed each day of the field study. Since the number of hours of data collection varied by day, the number of trucks per hour is also provided to be able to better compare truck volumes by day. The average number of trucks observed traversing the station per day over the two weeks of data collection was about 1,370. This equates to about 179 trucks per hour. Truck volume was greatest on Thursdays and generally higher toward the end of the week. Monday was the slowest day in terms of truck traffic. Data were not collected on weekends. Also, no data collector was present on July 12, and raw truck counts are lower on July 19 due to the station being closed in the late morning and entire afternoon.

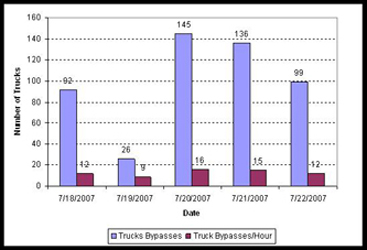

Figure 6-2 shows the total number of trucks and the number of trucks per hour that bypassed the station via NORPASS and hence were captured by the NORPASS system during the second week of the field study. An average of 13.5 trucks per hour bypassed the station via NORPASS during the 37 hours of data collection in the second week. The largest number of bypasses occurred Wednesday through Friday.

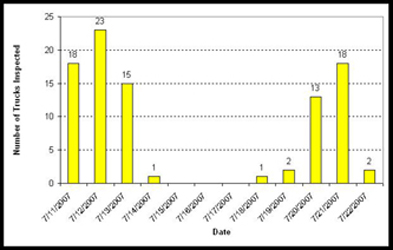

Figure 6-3 illustrates the number of inspections conducted per day at the station. The number of inspections per day varied throughout the course of the two-week study and was driven by the number of inspectors on duty on a given day. During the field study, Laurel County had two new KVE inspectors working for the first time. This was not believed to have a significant effect on the evaluation, nor on the number of inspections achieved per day. The prevailing attitude among inspectors at the time of the study was that the two new inspectors, once trained, might enable the KVE staff at the site to make better use of the ISSES data. The new inspectors were not observed to be using the ISSES equipment any more than the experienced inspectors assigned to the Laurel site. Since no data collector from the evaluation team was present on the weekends, no inspection data was collected on weekends either.

6.4.1 Carrier Demographics

The USDOT number for every truck observed during the field study was cross-referenced with the Motor Carrier Management Information System (MCMIS) Census File to obtain selected demographic information. A large percentage of the truck traffic, 95 percent, was interstate carriers, while the remaining 5 percent operated within the state of Kentucky. The large percentage of interstate carriers is not surprising, given that the station lies along I-75, a main corridor for north/south traffic in that part of the country, and is located just 30 miles north of the Tennessee border.

Table 6-5 shows a breakdown of the trucks' home states. Since license plate information was not captured on all trucks, the home state for each truck is defined as the base state of the truck's carrier as listed in the MCMIS Census File. Roughly 11 percent of the truck traffic was based in Kentucky. Another 25 percent of the trucks had carriers based in three of the states bordering Kentucky (Tennessee, Ohio, and Indiana). A large portion of the truck traffic hailed from the midwest and south with a small percentage based in western states.

| State | Number | Percent |

|---|---|---|

Kentucky |

1,387 |

10.82 |

Tennessee |

1,301 |

10.15 |

Ohio |

1,144 |

8.92 |

Indiana |

773 |

6.03 |

Michigan |

707 |

5.51 |

Arkansas |

685 |

5.34 |

Wisconsin |

593 |

4.62 |

Florida |

564 |

4.40 |

Illinois |

531 |

4.14 |

Ontario, Canada |

477 |

3.72 |

Georgia |

445 |

3.47 |

North Carolina |

409 |

3.19 |

Pennsylvania |

333 |

2.60 |

Nebraska |

288 |

2.25 |

Iowa |

283 |

2.21 |

Alabama |

263 |

2.05 |

Arizona |

243 |

1.89 |

Missouri |

235 |

1.83 |

Texas |

221 |

1.72 |

Minnesota |

194 |

1.51 |

South Carolina |

183 |

1.43 |

Virginia |

175 |

1.36 |

New Jersey |

107 |

0.83 |

All Other States |

1,283 |

10.00 |

TOTAL |

12,824 |

100.00 |

6.4.2 Carrier Electronic Screening

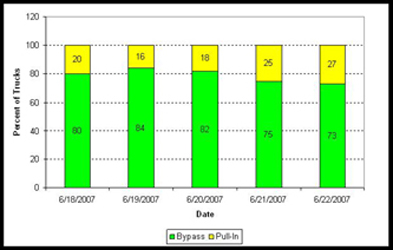

Of the 12,824 observed trucks that traversed the Laurel County inspection station during the times of field study data collection, 639 (or 5 percent) contained a transponder enrolled in NORPASS. Seventy-eight percent of the 639 e-screening participating trucks were allowed to bypass the station while the remaining 22 percent were instructed to pull into the station. This observed pull-in percentage is consistent with what would be expected given the NORPASS pull-in rates provided in Table 6-2. Figure 6-4 illustrates the percentage of trucks that bypassed and pulled into the station each day for the second week of the study. The percentages are fairly consistent across the five days, with a slightly higher pull-in rate on Thursday and Friday.

Table 6-6 displays the percentage of trucks that pulled into the station at the direction of NORPASS broken down by the reasons they were pulled in. Over half of the trucks were pulled in because of no weight data available from the mainline WIM. KTC officials commented that weight data may not be available in cases where a truck is straddling the WIM or there is a significant cargo shift while crossing the WIM. This also could indicate a technical problem with the WIMs. Eighteen percent were selected randomly for pull-in, while 13 percent had problems with their credentials or they were identified as a PRISM carrier. About 11 percent were brought in for a weight violation.

| Reason for Pull-In | Percentage of Trucks |

|---|---|

Credentials related or PRISM Carrier |

12.6% |

No weight data |

58.2% |

Random Selection |

17.9% |

Weight Violation |

11.4% |

6.4.3 Carrier Risk

The carriers' ISS scores were used to assess their safety risk. ISS is a decision aid for CMV roadside driver/vehicle safety inspections, which guides safety inspectors in selecting vehicles for inspection. The underlying inspection value is based on data analysis of the motor carrier's safety performance record using information from FMCSA's MCMIS. It is primarily based on SafeStat with an additional carrier-driver-conviction measure. SafeStat ranks all carriers by their safety performance in areas of crash history, inspection history, driver history, and safety management experience (UGPTI 2004). The system provides FMCSA with the capability to continuously quantify and track the safety status of motor carriers, especially unsafe carriers. This allows FMCSA enforcement and education programs to effectively allocate resources to carriers that pose a high risk of involvement in crashes. The ISS provides a three-tiered recommendation, as shown in Table 6-7.

| Recommendation | ISS Inspection Value | Risk Category |

|---|---|---|

Inspect (inspection warranted) |

75 - 100 |

High |

Optional (may be worth a look) |

50-74 |

Medium |

Pass (inspection not warranted) |

1-49 |

Low |

The USDOT numbers for the 12,824 trucks observed at the inspection site were compared with a copy of the SAFER database obtained at the time of the field study to obtain the ISS score for each carrier that could be identified. Trucks were then placed into risk categories based on Table 6-7. Carriers were placed into an "insufficient data" risk category if there was not enough information to generate an ISS score. Carriers with USDOT numbers that could not be found in SAFER were labeled as unknown. The distribution of safety ratings was also generated for all active carriers in the SAFER database at the time of the field study so that a comparison could be made between the relative safety risk for the population of Kentucky traffic around the Laurel County station and the population of CMVs nationally.

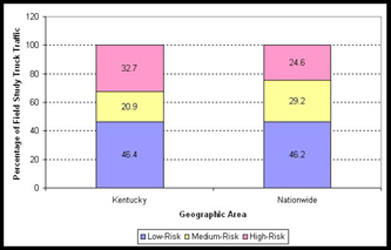

Figure 6-5 shows the percent of Kentucky field study truck traffic that fell into each risk category based on each carrier's ISS score, compared with the risk breakdown of all active trucks in SAFER at the time of the field study. A large proportion of the carriers in SAFER, however, about 81 percent, do not have sufficient information to generate an ISS score based on safety information (as opposed to less than 8 percent of the field study truck traffic). This skewed the risk distribution for the national truck population toward the Insufficient Data risk category. To better compare the Kentucky carriers with the national carriers, only carriers with sufficient information from SAFER were used. Also, unknown carriers (ones where USDOT numbers could not be matched to SAFER) were removed from this particular comparison.

About 33 percent of the Kentucky field study truck traffic is considered high-risk based on ISS while 21 percent and 46 percent are considered medium- and low-risk, respectively. The percentage of national high-risk carriers is lower than in Kentucky. As mentioned previously, there were a large number of carriers in SAFER with insufficient information to place them in a risk class—much more so than in the truck traffic for Kentucky. Furthermore, an examination of historical inspection reports from Kentucky has indicated that carriers with insufficient data to generate an ISS score have OOS rates comparable to those trucks in the high-risk category. Consequently, the exclusion of all carriers from SAFER with insufficient data may be artificially lowering the percentage of high-risk carriers from a national perspective. Regardless, the risk distribution of Kentucky truck traffic does not differ dramatically from that of the national risk breakdown. Furthermore, the percentages of trucks by risk are relatively consistent with results obtained from three other field studies conducted in Colorado, New York, and Ohio as part of the separate Evaluation of the National CVISN Deployment Program (not shown here). As a result, it is reasonable to assume that the traffic near the Laurel County station is comparable to the national population of carriers from a risk standpoint.

- Kentucky truck traffic based on 11,515 observed trucks during June 11 – June 22, 2007 with sufficient information to calculate ISS score.

- National data based on approximately 219,000 carriers in SAFER Carrier Table with sufficient information to calculate ISS score.

In addition to assessing the safety risk distribution for Kentucky truck traffic versus the national carrier population, risk classification was also used to compare different segments of the Kentucky truck traffic observed during the field study. Table 6-8 examines the risk distribution (based on ISS scores) of Kentucky field study trucks with and without transponders.

| ISS Risk Classification | # of KY Field Study Trucks Screened with Transponder | % | # of KY Field Study Trucks Screened without Transponder | % |

|---|---|---|---|---|

High |

83 |

13.0 |

3,677 |

30.2 |

Medium |

91 |

14.2 |

2,315 |

19.0 |

Low |

459 |

71.9 |

4,890 |

40.1 |

Insufficient Data |

4 |

0.6 |

996 |

8.2 |

Unknown |

2 |

0.3 |

307 |

2.5 |

Total |

639 |

100.0 |

12,185 |

100.0 |

Of all trucks participating in e-screening, about 72 percent are classified as low-risk compared to only 40 percent of non e-screening participating carriers. Thirteen percent of e-screening carriers are in the highest risk class as opposed to more than 30 percent of trucks without transponders. This is not surprising, because carriers with better safety records are more likely to enroll in e-screening than carriers with poorer safety records.

Table 6-9 examines the risk distribution of all e-screening participating carriers who were given a green light to bypass the station as well as those instructed to pull into the station. Based on the objectives of e-screening, one would expect a larger percentage of high-risk trucks to be pulled in versus allowed to bypass. The data support this expectation as the set of bypassed trucks have a lower percentage of high-risk trucks (about 11 percent) compared to the trucks instructed to pull in (about 21 percent). Again this is not surprising given that the rate in which trucks are pulled into stations is higher for those trucks with higher carrier's vehicle and driver OOS rates. Lower risk trucks are pulled in less frequently.

| ISS Risk Classification | # of KY Field Study Trucks that Bypassed Station | % | # of KY Field Study Trucks that Pulled In | % |

|---|---|---|---|---|

High |

53 |

10.6 |

30 |

21.3 |

Medium |

78 |

15.7 |

13 |

9.2 |

Low |

361 |

72.5 |

98 |

69.5a |

Insufficient Data |

4 |

0.8 |

0 |

0.0 |

Unknown |

2 |

0.4 |

0 |

0.0 |

Total |

498 |

100.0 |

141 |

100.0 |

6.5 Inspection Efficiency

For purposes of this evaluation, inspection efficiency is defined by the degree to which inspectors choose high-risk trucks for inspection. A high-risk truck is one where there is a high likelihood that the truck is operating with a serious OOS condition. There are multiple ways to define the risk associated with a truck. Two methods explored in this section are: (1) the carrier's ISS score, a rating system promoted by USDOT; and (2) a carrier's vehicle and driver OOS rates, which are the metrics currently preferred by Kentucky in roadside enforcement.

6.5.1 Risk Categories Using Carrier ISS Score

The data that were needed to assess the efficiency of the current inspection practices included the following:

- ISS Risk classifications for trucks in the population at the inspection site (based on observed truck traffic during field study);

- ISS Risk classifications for trucks that were inspected (based on approximately 2.5 years of state inspections in Kentucky); and

- OOS rates by ISS risk classification, historically, and during the field observational studies.

As discussed in Section 6.4.1, trucks observed at the inspection site were placed into one of five risk categories based on the carrier's ISS score. Using the same methodology, risk classifications based on the ISS score were also obtained for trucks inspected at both the Laurel County north- and southbound stations from January 2005 through mid-September 2007. In order to obtain OOS rates by risk category, the historical inspection records were used to determine whether each inspection over the 32.5 month timeframe resulted in an OOS order being issued. OOS rates were expressed as the number of OOS orders given per 100 inspections for each risk category.

For trucks inspected anywhere in Kentucky from January 2005 through mid-September 2007, the carrier's risk category at the time the inspection took place is not known. The risk category used in the present analysis is based on a copy of SAFER obtained during the field study. The assumption here is that a carrier's current risk rating is the same as when the carrier's vehicle was inspected. A carrier's rating could, of course, have changed over the 2.5-year period. However, based on the availability of SAFER datasets, the rating was assumed to remain constant.

6.5.2 Risk Categories Using Carrier's Vehicle and Driver OOS Rates

Kentucky's use of OOS rates to select vehicles for inspection was described in Section 6.2. For purposes of this discussion, driver OOS rates are multiplied by 3 to make the vehicle and driver OOS rates more comparable numerically. Also, high-risk vehicles are defined as those operated by a carrier with a vehicle or driver OOS rate of at least 25 percent. Medium-risk vehicles are those with a vehicle or driver OOS rate between 10 and 25 percent. Low-risk carriers have OOS rates of at most 10 percent.

OOS rate risk classifications were obtained for the observed truck traffic during the field study as well as vehicles inspected at the north- and southbound Laurel County sites over the previous 2.5 years by cross-referencing each vehicle's USDOT number with the Kentucky Clearinghouse. Then, because there is a wide range of OOS rates for each risk category (e.g., 76 to 99), the average OOS rate for all carriers in each OOS risk category was calculated using historical state inspections. This average number of OOS orders was used in the safety benefits analysis.

6.5.3 Using Carrier ISS Score to Define Truck Risk

Table 6-10 summarizes the inspection efficiency at the Laurel County inspection station in terms of the probability of selecting high-risk trucks. Actual vehicle inspection totals by risk category in the first row are based on more than 17,000 inspections performed at the Laurel County north- and southbound stations between January 1, 2005, and September 13, 2007. Since only 93 trucks were inspected at the northbound ISSES site during the two-week field study,4 the use of the historical inspections provided a more robust risk distribution of inspections. Also for this reason, inspections from the southbound Laurel County station were included. The southbound station is located on the other side of the highway and is similar in layout to the northbound station, with the exceptions that the southbound station does not have an ISSES, and the southbound station has both the low-speed bypass lane and the static scale lane on the east (highway) side of the scale house. The truck traffic vehicle totals in the second row are based on the total number of trucks observed traversing the station during the field study. The vehicles selected for inspection as well as those in the truck traffic population were divided into high-, medium-, and low-risk, insufficient data, and unknown risk based on the ISS scores of the carrier and are shown in columns 2 through 5 of Table 6-10.

For the inspected and truck traffic vehicles, the probability of a truck being high-risk is shown. The probability of a truck being in the high-risk category is calculated as the number of high-risk trucks divided by the total number of trucks. About 29 percent of the truck traffic at Laurel County was considered high-risk, while 34 percent of the vehicles inspected at the Laurel County station were high-risk. The ratio of the proportion of high-risk vehicles inspected to the proportion in the truck traffic population is 1.16 (33.94 percent divided by 29.32 percent). This ratio is statistically significantly greater than 1 (the value expected if there was no difference between random inspections and current practices). Thus, current inspection practices such as inspector judgment, visual observation of vehicles, and use of NORPASS for transpondered vehicles yield slightly more high-risk trucks than if inspectors would simply choose trucks randomly.

| Vehicle Data | Number of Trucks by Risk Classification | Percent of High-Risk Carriers | ||||

|---|---|---|---|---|---|---|

| High | Med/ Low | Insuff. Data | Unknown | Total | ||

Inspected(1) |

5,929 |

10,502 |

987 |

53 |

17,471 |

33.94% |

Truck Traffic(2) |

3,760 |

7,755 |

1,000 |

309 |

12,824 |

29.32% |

Inspected vs. Truck Traffic |

1.16 |

|||||

(2)* Truck Traffic totals based on more than 12,800 trucks observed during two-week field study at Laurel County Station

The analysis comparing OOS rates for different inspection selection strategies requires estimates of OOS rates across risk categories. Table 6-11 shows statewide OOS rates by risk categories, which were calculated using all inspections in Kentucky between January 1, 2005, and September 13, 2007. OOS rates were 7.2 per 100 inspections for low-risk trucks and 17.2 per 100 inspections for high-risk trucks. OOS rates for trucks with insufficient data and for an unknown risk class were higher than those for high-risk trucks. The overall OOS violation rate was 13.6% over the 32.5-month span.

| Risk Class (Based on ISS Score) | Number of Inspections | Number of Inspections with an OOS Violation | OOS Rate (No. per 100 Inspections) |

|---|---|---|---|

High-Risk |

70,803 |

12,183 |

17.2 |

Medium-Risk |

40,818 |

5,597 |

13.7 |

Low-Risk |

80,225 |

5,763 |

7.2 |

Insufficient Data |

26,384 |

5,072 |

19.2 |

Unknown |

4,222 |

1,561 |

37.0 |

Total |

222,452 |

30,176 |

13.6 |

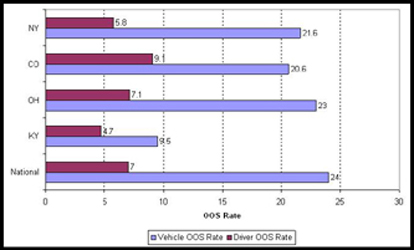

Kentucky's historic OOS rates were found to be significantly below the national average. Nationally, 24 percent of vehicles inspected were put OOS for vehicle violations and 7 percent of drivers inspected were put OOS for driver violations in 2005 (USDOT 2005b). Based on Kentucky inspections performed from January 1, 2005, through September 13, 2007, Kentucky's vehicle and driver OOS rates for 2005 were 9.5 percent and 4.7 percent, respectively. Representatives of the KTC acknowledged that Kentucky's OOS rates are below the national average and that FMCSA and the Commissioner of KVE have identified the raising of OOS rates as a priority. The KTC has been performing a detailed analysis of Kentucky's OOS rates in an attempt to better understand the difference in OOS rates between Kentucky and the rest of the nation. At the time of this evaluation, no results or conclusions from this analysis were available. More discussion on the relatively low Kentucky OOS rates is provided in Section 6.6.

Table 6-12 presents the results of the analysis of OOS rates. The expected number of OOS orders was calculated for two scenarios: if trucks were selected randomly for inspection, and if trucks were selected according to current practices. The expected number of OOS orders per 100 inspections under each of these scenarios was calculated by multiplying the proportion of trucks in each risk category by the OOS rate for that category. That is, the number of OOS orders per 100 inspections was equal to the proportion of those 100 inspections that would be expected to be in the risk category multiplied by the OOS rate for the risk category. For example, the table illustrates that about 29 percent of trucks observed during the field study were classified as high-risk compared to roughly 34 percent of the inspections conducted at the Laurel County station. The state OOS rate for the high-risk category is 17.2. Thus, the expected number of OOS orders per 100 random inspections of high-risk trucks would be 5.04 (29.32*0.172). Using current inspection practices, the expected number of OOS orders per 100 inspections for high-risk trucks is 5.84 (33.94*0.172). Within each inspection selection scenario, the sum of the corresponding numbers over all five risk categories gave the total number of OOS orders expected per 100 inspections.

| ISS Risk Category | Percentage of Commercial Vehicles< | State OOS Rate | No. OOS Orders per 100 Inspections | ||

|---|---|---|---|---|---|

| Random Selection(1) | Inspected(2) | Random Selection | Inspected | ||

High |

29.32 |

33.94 |

17.2 |

5.04 |

5.84 |

Medium |

18.76 |

18.43 |

13.7 |

2.57 |

2.52 |

Low |

41.71 |

41.68 |

7.2 |

3.00 |

3.00 |

Insufficient Data |

7.80 |

5.65 |

19.2 |

1.50 |

1.08 |

Unknown |

2.41 |

0.30 |

37.0 |

0.89 |

0.11 |

Total Expected OOS Orders per 100 Inspections |

13.00 |

12.55 |

|||

(2) Actual selection percentages are based on more than 17,000 inspections performed at the Laurel County northbound and southbound stations between January 1, 2005 and September 13, 2007.

Overall, if trucks were selected for inspection at random, one would expect about 13 OOS orders per 100 inspections. Using the current inspection selection procedure, the number of OOS orders per 100 inspections would be expected to drop 0.45 OOS orders per 100 inspections. Although the number of OOS orders for high-risk trucks increases, the slight overall drop in OOS orders is due mainly to the lower percentage of insufficient data carriers that are inspected compared to the percentage of carriers with insufficient data in the truck traffic population. This is a consequence of Kentucky focusing on OOS rates as a measure to select high-risk trucks—if any historical safety data were used at all—and not using ISS scores to select vehicles for inspection. Moreover, the state OOS rate for insufficient data carriers is quite high at 19.2 OOS orders per 100 inspections. Thus, current inspection selection practices do not yield an improvement in the number of OOS orders over selecting trucks randomly.

Table 6-13 illustrates the impact on the number of OOS orders per 100 inspections where an inspection selection strategy is adopted that incorporates the use of full electronic screening. Under this hypothetical scenario, all CMVs classified as low- and medium-risk enroll in NORPASS, are equipped with transponders, and are allowed to bypass inspection sites. Inspectors then use current practices to select vehicles for inspection from the remaining trucks in the high-risk and insufficient data categories. The second column again shows the risk distribution of trucks that would be expected if trucks were selected randomly for inspection. The third column shows the proportion that would be inspected if all low- and medium-risk trucks were allowed to bypass the site and if the numbers for the remaining risk categories were increased proportionally. For example, the percentage of high-risk trucks expected to be inspected under this strategy would be 74.17 percent {74.17% = 29.32% / [1-(0.1876+0.4171)]}, while no medium- or low-risk trucks would be inspected. As in the preceding table, the expected number of OOS orders per 100 inspections under each of these two scenarios was calculated by multiplying the proportion of trucks in each risk category by the OOS rate for that category. Within each inspection selection scenario, the sum of the corresponding numbers over all five risk categories gave the total number of OOS orders expected per 100 inspections.

| ISS Risk Category | Percentage of Commercial Vehicles | State OOS Rate | No. OOS Orders per 100 Inspections | ||

|---|---|---|---|---|---|

| Random Selection(1) | Full ES(2) | Random Selection | Full ES | ||

High |

29.32 |

74.17 |

17.2 |

5.04 |

12.76 |

Medium |

18.76 |

0.00 |

13.7 |

2.57 |

0.00 |

Low |

41.71 |

0.00 |

7.2 |

3.00 |

0.00 |

Insufficient Data |

7.80 |

19.73 |

19.2 |

1.50 |

3.79 |

Unknown |

2.41 |

6.10 |

37.0 |

0.89 |

2.26 |

Total Expected OOS Orders per 100 Inspections |

13.00 |

18.81 |

|||

(2) Distribution was derived from random selection percentages and the assumption that electronic screening will eliminate low and medium-risk carriers from the selection process (e.g., for high-risk category 74.17% = 29.32% / (1-(0.1876+0.4171))).

Again, if trucks were selected for inspection at random, one would expect about 13 OOS orders per 100 inspections. If electronic screening were implemented to the point that all low- and medium-risk trucks would be allowed to bypass the site, the number of OOS orders per 100 inspections would be expected to rise to about 19. This last scenario represents an increase of OOS orders per 100 inspections of about 45 percent from the scenario where trucks are randomly selected for inspection from the population of traversing trucks. It also represents an increase of OOS orders per 100 inspections of about 50 percent compared to current inspection practices.

6.5.4 Using Carrier OOS Rates to Define Truck Risk

Rather than ISS scores, Kentucky uses a carrier's driver and vehicle OOS rate to determine those trucks that should be selected for inspection at stations where an office support assistant is assigned. Trucks observed during the field test were placed into risk categories based on their vehicle OOS rate or their driver OOS rate (multiplied by three), whichever is higher. Carriers with higher vehicle or driver OOS rates are placed into higher risk categories. In turn, the higher the risk category that a truck belongs to, the higher the probability that the truck would be kicked out for inspection.