| Introduction | |

Performance-related specifications (PRS) have capabilities beyond

traditional QA specifications. These capabilities include clearly defining

lots and sublots (for all sampling and testing), the subsequent sampling

and testing of key AQC's that relate directly to the future performance of

the constructed pavement, and predicting future LCC's used to compute

contractor pay adjustments (incentives and disincentives). Thus, the level

of quality (expressed as a mean and standard deviation) achieved for each

of the key AQC's can be related directly to rationally computed pay

adjustments based on sound economic principles.

The initial

ground-breaking work on PRS was done by R.M. Weed for the New Jersey

Department of Transportation.(7) This work provided a basis for

the prototype PRS developed under a previous FHWA research study. (See

references 1, 2, 3, and 8.) The prototype used an innovative approach that

considered the estimated future LCC of the pavement as the overall measure

of quality. Under the prototype, target values (means and standard

deviations) must be established for four key AQC's (concrete strength,

slab thickness, entrained air content, and initial smoothness). These

AQC's are then measured from the in situ pavement during construction. The

computed as-constructed AQC lot means are then used in established

mathematical models to predict key distress indicators (transverse joint

faulting, transverse cracking, transverse joint spalling, and PSR) over a

chosen analysis period. The amount of the pay adjustment is then based on

the AQC quality-related increase or decrease in future LCC's expected to

be incurred by the agency over the chosen analysis life of the project

(assuming a given rehabilitation policy). A computer software program,

PaveSpec, was developed to demonstrate the prototype

specification.

Although the prototype PRS were based on rational

concepts, researchers realized that an attempt to implement such

specifications would most likely be met with resistance. This resistance

would result from the general unfamiliarity with the current PRS concepts,

the dependency of computed pay adjustments on the PaveSpec software, the

additional costs associated with strongly emphasized in situ testing, and

the need to simulate the actual pay factor in the field. Under the current

research project, a strategy was developed to aid in the acceptance and

implementation of the revised prototype PRS. This involved the development

of three different PRS implementation levels. Each of these is described

in detail in the following section.

| Three Levels of PRS Implementation | |

The overall goal of PRS research is to progress toward developing ideal PRS that incorporate all important AQC's of PCC pavements that not only affect pavement performance, but are also under the control of the contractor. As a means of achieving this goal, future research should attempt to:

- Identify distress indicators that significantly affect pavement

performance (these drive the PRS).

- Identify the AQC's and other variables that directly affect each

identified distress indicator.

- Develop early age, rapid, reliable, easy, and cost-effective field

tests that measure the in situ quality level of each identified

AQC.

- Develop accurate distress indicator prediction models that are

dependent on the measured quality level mean and variability of each

identified AQC (none of the current models are directly dependent upon

variability).

- Develop a practical, yet comprehensive, method for the calculation

of overall lot pay adjustments using sound economic principles.

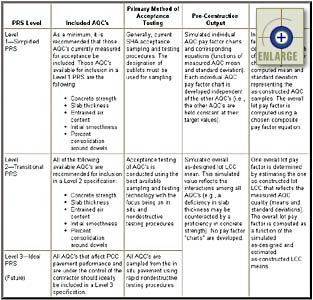

Obviously, much research is needed to develop and implement an ideal PRS. Such an effort will take much more research and funding. Therefore, as a means of organizing the envisioned work needed to develop these ideal PRS, three different levels (chronological steps) of PRS implementation were proposed. These three levels are defined as follows:

- Level 1—Simplified PRS:Developed as a simplified version of the original prototype PRS. It is believed that the current Level 1 acceptance testing would not differ greatly from the procedures currently used by SHA's. AQC quality can be approximately assessed using selected parts of the agency's current AQC sampling and testing methods for core strength, entrained air content, slab thickness, percent consolidation around dowels, and initial smoothness.

The Level 1 pay factor computation method is based on calculating independent pay factors for each AQC (all other AQC's are assumed to be equal to the target values). Each of these pay factors is determined from a series of developed pay factor versus AQC mean curves. These curves, each specific to a different as-constructed AQC standard deviation, are created by correlating simulated lot pay factors over a range of AQC means. Each computed pay factor is, therefore, a function of the measured as-constructed mean and standard deviation, target mean and standard deviation, and sample size. Final payment for the lot is based on a chosen CPF equation (expressed as a simple mathematical function of the independently determined AQC pay factors). This Level 1 CPF is an estimate of the pay factor determined using the more rigorous procedures of Level 2.

- Level 2—Transitional PRS: The Level 2 specifications generally use the same concepts and procedures developed for the original prototype PRS.(1,2,3) The Level 2 specifications represent the dynamic transition from the original prototype specifications presented in the final report of a previous FHWA research project to the ultimate goal of Level 3.(1,2,3) The Level 2 PRS encourage the use of more in situ and nondestructive sampling and testing that can be used to accept pavement lots at much earlier ages (e.g., using 3-day core compressive strength results for the acceptance of concrete strength). The Level 2 PRS also require more computer simulation to compute pay adjustments.

The Level 2 pay factor computation method calculates lot pay factors by directly comparing simulated as-designed (target) and as-constructed LCC's. Interactions of AQC's are included in the simulations (e.g., an increase in concrete strength may counteract a deficiency in slab thickness). The pay factor calculation is based on the premise of liquidated damages. Final payment for the lot is based on the simulated pay factor determined using the PaveSpec software.

- Level 3—Ideal PRS: The Level 3 specifications represent the

ideal specifications that will eventually be achieved with much future

research. Such specifications would include many more AQC's that are

not currently measurable. Also, these AQC's would be measured using

reliable early age methods that are both in situ and

nondestructive.

The original PRS prototype and corresponding computer program (PaveSpec) have been updated and revised under this current research project. The revised PRS prototype addresses both Level 1 and Level 2 PRS acceptance procedures and is included as appendix A (in this volume).

Table 1.

Details of the three proposed PRS implementation levels.