| Introduction | |

This chapter provides a number of key concepts related to the current PRS approach that must be understood before attempting to use the revised PRS prototype. The chapter starts with a general discussion of pavement performance and how it is defined under the PRS approach. The specific step-by-step PRS procedure used to predict the performance of a given lot is presented. Next, the concept of computing and using the lot LCC as the overall measure of quality (for both the as-designed and as-constructed pavements) is explained. The step-by-step procedures used to compute an overall lot LCC are discussed. Finally, the procedures used to compute Level 1 and Level 2 pay adjustments (based on the estimated as-designed and as-constructed LCC's) are explained.

| Prediction of Pavement Performance | |

The underlying concept of PRS is that knowledgeable decisions related to pavement lot acceptance and corresponding pay adjustments are based on the predicted pavement performance. Under the current PRS approach, pavement performance is expressed in terms of different identified pavement distresses, referred to as distress indicators. In a previous PRS study, many distress indicators were identified that were not only assumed to have a significant effect on the service life of the pavement, but were also under the control of the contractor.(1) Based on each identified distress indicator's significance to concrete pavement performance and the availability of mathematical-based prediction models, the following four distress indicators were selected for inclusion in the original, and also the revised, prototype PRS:(1)

- Transverse joint spalling.

- Transverse joint faulting.

- Transverse slab cracking.

- Pavement smoothness over time.

Although the chosen distress indicators are exclusively related to the

concrete slab, distress indicators related to other pavement components

(such as the subgrade, base, and shoulders) should eventually be included

in more comprehensive PRS. The current PRS methodology allows for the

eventual inclusion of any number of distress indicators.

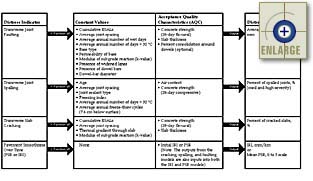

These four

distress indicators included in the revised PRS are predicted over a

chosen analysis period using the best prediction models available. These

mathematical models are functions of a series of defined project-specific

constant values (e.g., traffic, climatic variables, design

characteristics, drainage and support conditions, project dimensions, and

unit costs) and relevant AQC sample means. The general inputs and outputs

for each of the available PRS distress indicator models are shown in

figure 1.Each distress indicator model is explained in detail in appendix

E (volume III).

|

Figure 1. Inputs and outputs of the distress indicator prediction models available in the revised PRS prototype. |

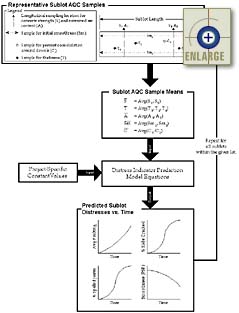

Although pay adjustments are applied on a lot basis, pavement performance is predicted for each sublot under the current PRS approach. A sublot is a discrete amount of pavement (part of a lot) from which AQC's are measured. A chosen number of AQC samples are taken from each sublot and tested using agency-approved testing procedures. Note that the number of samples per sublot may differ for each AQC. The sublot means of the AQC testing values, and the project-specific constant values, are then used in the distress indicator models to predict the respective sublot distresses over time. This procedure is repeated for every sublot within a lot; therefore, the performance of the entire lot is defined in terms of the independently predicted sublot distresses. Because the predicted sublot distresses are dependent on the representative sublot AQC means, changes in the between-sublot quality level impact the predicted between-sublot performance. Figure 2 illustrates an example of the procedure used to predict the pavement performance of a given lot. (Note: The AQC sampling types and frequencies chosen for this example are for illustration purposes only.)

|

Figure 2. Process for predicting the pavement performance of a given lot (sample types and number of samples per sublot are for illustration purposes only). |

| LCC as the Overall Lot Quality Characteristic | |

A driving concept of the current PRS approach is that the predicted future LCC of a pavement lot is the overall quality characteristic used for determining contractor pay adjustments. The lot LCC can generally be defined as the cumulative PW value of the future pavement performance-related costs expected to be incurred by the SHA (and users, if so desired) over the chosen analysis period. This LCC definition is, of course, very much dependent on what specific types of costs the agency chooses to include. Under the current PRS approach, the agency may choose to consider not only expected M & R costs, but user costs as well. Each of the specific cost types available for inclusion are discussed in more detail below.

The costs incurred by the agency include all of the M & R costs

expected to be required to keep the pavement lot in service (at an

acceptable quality level) over the chosen analysis period. Rehabilitation

costs are divided into localized and global rehabilitation costs. Each of

these agency-incurred cost types is discussed separately

below.

Maintenance costs are those costs associated with the

application of day-to-day maintenance activities performed to address

safety and operational concerns and prevent the rapid deterioration of the

pavement structure. These activities are generally referred to as

preventive or routine maintenance. This maintenance is

typically applied at certain fixed intervals of time over the life of a

pavement lot (commonly on an annual basis). The current PRS approach

limits maintenance costs to those resulting from transverse crack and

transverse joint sealing.

Local rehabilitation costs are those

resulting from the application of localized rehabilitation activities

(used to correct localized distresses). Localized distresses are those

that affect an individual joint (transverse joint spalling and transverse

joint faulting) or an individual slab (transverse slab cracking). The

current PRS approach considers costs resulting from the following local

rehabilitation activities:

- Full-depth or partial-depth repairs addressing transverse joint spalling.

- Full-slab or partial-slab replacements addressing transverse slab cracking.

Global rehabilitation costs are those costs resulting from activities applied to the entire pavement lot in response to declining global pavement conditions. These activities are specifically applied to address pavement conditions such as decreasing pavement smoothness, increasing amounts of localized distress, or increasing amounts of applied localized rehabilitation. These activities are referred to as global because they are applied to the entire lot (all sublots) at the same point in time (based on the consideration of the individual performance of all sublots within the lot). In the current PRS approach, global rehabilitation costs can be the result of AC overlays, PCC overlays, or diamond grinding.

The concept of having the contractor pay adjustment dependent on estimated future costs incurred by pavement users has long been debated when discussing PRS. User costs are defined as pavement condition-related costs incurred by the users of the facility over the chosen analysis period. The current PRS approach allows the consideration of the following four user cost types defined by McFarland and presented in a recent report discussing LCC's:(10,13)

- Travel-time costs—motorist delay costs spurred by detours, work

zones, or closures associated with construction, rehabilitation, and

maintenance activities. These costs can be a major portion of total user

costs. Rougher pavements can reduce traffic speeds, representing another

source of travel-time costs.

- Vehicle operating costs—costs associated with fuel and oil

consumption, tire wear, emissions, maintenance and repair, and

depreciation. Like travel-time costs, these costs make up a significant

percentage of the total user costs.

- Accident costs—costs associated with accidents due to rough or

slippery roads. American Association of State Highway and Transportation

Officials (AASHTO) has subdivided accident costs into fatal accidents,

nonfatal accidents, and property damage.(14)These costs can

be a significant portion of the total user costs; however, they are very

difficult to estimate because the value of a human life and the cost of

a debilitating injury are very controversial.

- Discomfort costs—costs associated with rough roads. This category is probably the most difficult to estimate and generally contributes little to total user costs in North America, particularly in light of the smoother pavements required for heavily trafficked pavements.

The inclusion of user costs in the lot LCC's used to compute PRS pay adjustments continues to be a controversial issue. In response, the revised prototype PRS allows for the inclusion of a specified percentage of the estimated total user costs over the chosen analysis period. This percentage may be set equal to zero if an agency does not wish to include any user costs. The inclusion of user costs does, however, allow the SHA to emphasize the effects of pavement smoothness on LCC's and subsequent pay adjustments.

Calculation of the Representative LCC for a Given Lot

The calculation of the representative LCC for a given lot is based on

estimating all of the future maintenance, rehabilitation, and user costs

(if included) related to the predicted performance of the given lot. The

performance of the lot, defined in terms of sublot distresses versus time,

is predicted using the procedure outlined in figure

2. An agency-defined M & R plan is applied to these streams of

sublot distresses in order to determine when and what type of M & R

activities are expected to be applied. Typically, a series of defined

pavement conditions (individual distress levels, combinations of distress

levels, and limits on the number of applied localized repairs) is used to

trigger localized and global rehabilitation.

Following is the

step-by-step procedure used to determine the particular timing of M &

R activities and their associated costs, which are, in turn, summarized

into a representative lot LCC.

- Determine the estimated yearly maintenance and local

rehabilitation activities for each sublot. As the pavement

distresses are predicted for each sublot at each year over the chosen

analysis period, M & R activities are applied to each sublot in

accordance with the agency-defined M & R plan. The details of the M

& R plan can be based on time (e.g., replace cracked slabs every 5

years) or individual distress volume (e.g., replace spalled joints when

20 percent of the joints are spalled). Figure 3 shows an example of the

relationships between the predicted distress indicators and the

application of corresponding localized rehabilitation for a given sublot

(as defined by the applicable M & R plan).

Figure 3. Example of the relationships between the predicted distress indicators and the application of corresponding localized rehabilitation for a given sublot. The schedule of applied maintenance is slightly more complex, as it depends not only on the scheduled timing of the maintenance activities (defined in the M & R plan), but also on the amounts of the predicted localized distress. For example, as the total linear feet of predicted slab cracking increases, so does the amount of required crack sealing. Similarly, every transverse joint that is replaced to correct spalling results in two new joints (both sides of the new patch) that require sealing.

- Determine the year of first global rehabilitation. The lot

LCC is greatly influenced by the chosen timing and type of global

rehabilitation activities. This is primarily due to the magnitude of

these costs in relation to the maintenance and localized rehabilitation

costs. The revised prototype provides the agency with the following two

options for determining when the first global rehabilitation is to be

applied to the entire lot:

- Lot threshold trigger values on distress or localized rehabilitation values—The first option involves identifying lot threshold trigger values to be applied to either the cumulative sublot distresses or cumulative localized rehabilitation activities predicted to occur in all sublots within the lot. Specifically, this may involve a comparison of any or all of the following types of items to predetermined critical lot threshold trigger values:

- Individual distress indicators—i.e., percent (or

number) of cracked slabs, percent (or number) of spalled joints,

and average faulting per joint.

- Combinations of individual distress indicators—e.g.,

apply global rehabilitation if percentage of cracked slabs = 20

percent and percentage of spalled joints = 30 percent.

- Applied levels of localized rehabilitation—e.g., apply global rehabilitation when a total of 20 percent of the transverse joints have been repaired for spalling.

Predicted distresses, and their corresponding required localized rehabilitation, are estimated each year over the progressing life of the pavement. The computed cumulative distresses, or localized rehabilitation, are then compared to the agency-defined lot threshold trigger values. When a computed cumulative distress or localized rehabilitation value surpasses a predefined lot threshold trigger value, the first global rehabilitation is triggered for application at that age.

An example of this lot threshold trigger value method is illustrated in figure 4. For this example, the agency has chosen to determine the timing of the first global rehabilitation based on two different lot threshold trigger values: (1) if the cumulative percentage of replaced slabs due to cracking equals 20 percent or (2) if the average sublot PSR equals 2.5. Both of these trigger values are checked each year over the progressing life of the pavement. For this particular example, it is the average sublot PSR that is the controlling criterion, since it reaches its respective trigger value at an earlier age than the percentage of cracked slabs. The average sublot PSR reaches a value of 2.5 at an age of 17.5 years, while the percentage of cracked slabs did not reach its trigger value of 20 percent until year 19.25. Therefore, the first global rehabilitation is scheduled to be applied to the lot (all sublots) at an age of 17.5 years.

- Percentage of sublots failed (PSF)—The second option involves directly comparing the individually determined sublot distress or localized distress values (rather than the lot cumulative values) to agency-defined sublot threshold trigger values. When a distress or localized rehabilitation value for a sublot surpasses a predefined sublot threshold value, the sublot is labeled failed. This process is used to independently determine the estimated age of failure for each sublot in the lot. The agency then defines the timing of the global rehabilitation (for application to the entire lot) in terms of a PSF threshold value (e.g., an AC overlay will be applied to the entire lot when 20 percent of the sublots have been labeled as failed). When the computed PSF value equals the agency-defined PSF threshold value, the first global rehabilitation is triggered for application at that age.

Figure 4. Example of the lot threshold trigger method used to determine the timing of the first lot global rehabilitation. An example of this PSF method is illustrated in figure 5. For this example, the lot is made up of six sublots. The agency-defined PSF threshold value is 20 percent; therefore, this threshold value will be surpassed when two of six sublots are labeled as failed (33 percent > 20 percent). The independently determined sublot failure ages are shown for each sublot within the example lot. These sublot failure ages are then used to create a plot of PSF versus age. Based on the individually determined sublot failure ages and an agency-defined PSF threshold value of 20 percent, the first global rehabilitation is scheduled to be applied when the second sublot fails at an age of 19.50 years. It is strongly recommended that a trigger value of 10 to 30 PSF be used as the lot trigger value for determining global rehabilitation. This criterion is realistic and provides for a reasonable effect of variability on the LCC and pay adjustment.

Figure 5. Example of the PSF method used to determine the timing of the first lot global rehabilitation.

-

Determine types and life spans of additional global rehabilitation applications. After the timing of the first global rehabilitation is determined, the agency must define the types and timings of additional global rehabilitation applications. Each global rehabilitation activity is applied with an assumed life span (e.g., apply an AC overlay with an assumed 15-year overlay life). Additional global rehabilitation activities are then applied at the end of each assumed life span. (Note: Each additional global rehabilitation does not have to be of the same activity type as the preceding applied rehabilitation. For example, the agency could choose to apply diamond grinding for the first and second global applications, and then follow those with AC overlay applications until the end of the analysis period.) Global rehabilitation activities may have different assumed life spans (e.g., an AC overlay may be assumed to last 15 years, whereas diamond grinding may be assumed to last 8 years).

- Determine the estimated yearly maintenance and rehabilitation

costs for each sublot. The next step is to calculate the costs

associated with the predicted M & R application schedule.

Maintenance and localized rehabilitation costs are only incurred up

until the application of the first global rehabilitation. After the

application of the first global rehabilitation, a simplified maintenance

and localized rehabilitation plan (determined by the agency) is assumed.

Figure 6 shows an example of the estimation of different M & R costs

(for one sublot) as they are applied over the analysis life of the

pavement.

Figure 6. Example showing the estimation of different M & R costs for one sublot (over the chosen analysis life).

- Determine the estimated yearly user costs for each sublot

(optional). As mentioned previously, the prototype allows the

inclusion of a percentage of the estimated user costs. User costs

(accident, delay, discomfort, and vehicle operating) are computed as a

function of road type (e.g., two-lane-undivided, four or more

lanes-divided), yearly traffic, and level of smoothness. The process

starts with determining the current level of smoothness at the start of

each year of the analysis period. A user cost per vehicle per

kilometer is then determined as a function of road type and level of

smoothness. The expected amount of traffic (number of vehicles on the

pavement) for the year is then used to determine a total yearly user

cost value expressed in dollars per kilometer. Knowing the sublot

length allows for the calculation of actual user cost dollars associated

with that particular sublot. The agency-chosen percentage of

these calculated yearly user costs is then used to determine the

respective stream of yearly user costs for the given sublot. Note that

user costs are typically very large in comparison to the M & R costs

calculated in step 4.

- Determine the total present worth LCC for each sublot. The

stream of maintenance, rehabilitation, and user costs are next expressed

in terms of present worth costs using the defined present worth method.

Summarizing the yearly costs into one PW LCC representing the sublot is

key to the prototype approach. The sublot LCC's represent the overall

quality characteristic used to define the quality of each sublot (and,

therefore, the quality of each lot). Each estimated yearly cost is

expressed in terms of present worth by using equation 4. These specific

streams of yearly costs for each sublot are, therefore, translated into

PW sublot LCC's.

- Calculate the representative lot LCC. The final step in the calculation of the representative LCC for a given lot is to summarize all of the calculated sublot PW LCC's. Each sublot LCC is expressed in PW dollars rather than PW dollars per kilometer. Therefore, the representative lot LCC is calculated by summing all of the independently calculated sublot LCC's for the lot. The overall lot LCC may then be expressed in terms of PW LCC per kilometer by dividing the total lot present worth LCC by the appropriate lot length (in kilometers).

This entire lot LCC calculation process can be represented mathematically by the cost relationship shown in equation 7.

LCCLOT = S ALL SUBLOTS S YEARS [PW(MNT) + PW(LR) + PW(GR) + (A/100)*PW(UC)] (7)where

Chapter 4 continues...LCCLOT =Total present worth lot LCC, PW$.

PW(MNT) = Present worth of maintenance costs, PW$.

PW(LR) = Present worth of localized rehabilitation costs, PW$.

PW(GR) = Present worth of global rehabilitation costs, PW$.

A = Percentage of user costs to be included. (e.g., 3 percent is entered as 3).

PW(UC) = Present worth of user costs, PW$.